Introduction

PVC Coated Fabric is a versatile material that plays a significant role in the textile industry. Known for its unique properties, this fabric has gained popularity for various applications. Let’s delve into the fundamental characteristics of PVC Coated Fabric, including its composition, density, and its wide-ranging uses in the textile sector.

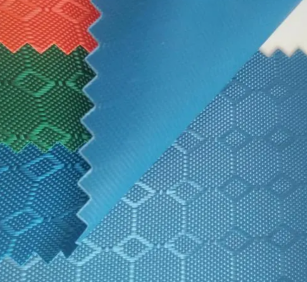

Composition and Characteristics

The Essence of PVC Coated Fabric

PVC Coated Fabric is crafted using a blend of high-quality materials, with the primary component being polyvinyl chloride (PVC). This synthetic material is known for its durability and resilience, making it an excellent choice for various applications. The fabric is woven with precision, resulting in a specific density that enhances its strength and longevity.

Unveiling the Versatility: Applications of PVC Coated Fabric

Outdoor Gear and Equipment

PVC Coated Fabric is commonly used in the manufacturing of outdoor gear and equipment such as backpacks, tents, and camping accessories. Its water-resistant properties make it well-suited for protecting against the elements.

Luggage and Bags

The fabric’s durability and resistance to wear make it an excellent choice for luggage and bags. Whether in the form of travel bags, backpacks, or business cases, PVC Coated Fabric ensures longevity and reliability.

Automotive Upholstery

Within the automotive industry, PVC Coated Fabric is utilized for upholstery in vehicles. Its robustness and resistance to abrasion make it a preferred material for enhancing the durability of interior components.

Fashion and Accessories

PVC Coated Fabric has also found its way into the fashion industry, being used to create stylish and durable accessories such as wallets, belts, and even certain types of footwear.

Advantages of PVC Coated Fabric

Abrasion Resistance

One of the standout features of PVC Coated Fabric is its remarkable abrasion resistance. The fabric is designed to withstand wear and tear, making it an ideal choice for products that are subjected to frequent use and friction. This quality ensures the longevity and durability of items crafted from PVC Coated Fabric, providing end-users with products that maintain their integrity over extended periods.

Waterproof Properties

PVC Coated Fabric is well-regarded for its excellent waterproofing capabilities. The fabric is coated with polyvinyl chloride (PVC), creating a protective barrier that repels water effectively. This characteristic makes PVC Coated Fabric an ideal choice for outdoor applications, including tents, rain gear, and bags, where resistance to moisture is crucial for both comfort and the protection of contents.

Tear Strength

Another noteworthy attribute of PVC Coated Fabric is its high tear strength. This fabric is engineered to resist tearing and ripping, ensuring that products made from it can withstand rough handling and harsh environmental conditions. Whether used in backpacks, luggage, or other items, the tear-resistant nature of PVC Coated Fabric adds an extra layer of reliability.

Easy Maintenance

PVC Coated Fabric is known for its ease of maintenance, making it a practical choice for products that require regular cleaning. The surface of the fabric is smooth and resistant to stains, simplifying the cleaning process. Whether dealing with dirt, spills, or other contaminants, PVC Coated Fabric can be easily wiped clean, maintaining its aesthetic appeal and functionality.

Crafting Your Vision with PVC Coated Fabric

Tailoring Options for a Personalized Touch

Once we have a clear understanding of the customer’s requirements, we present a range of options for color, thickness, and coating types. Our extensive selection allows customers to choose the combination that best suits their intended application. Whether it’s a vibrant color for a recreational product or a heavy-duty coating for industrial purposes, we offer a variety of choices to cater to diverse needs.

Collaborative Efforts for Precision

We strongly believe in collaboration, and our team works closely with the customer to refine the chosen specifications. Through open communication channels, we ensure that every detail is considered and that the customer is fully satisfied with the proposed fabric composition. This collaborative approach enhances the accuracy of the customization process and fosters a strong partnership between our factory and the customer.

Behind the Scenes: The Art and Science of Crafting PVC Coated Fabric

Yarn Selection and Preparation

The production journey begins with the careful selection of high-quality yarns. The yarns are chosen based on their strength, flexibility, and resistance to wear and tear. These selected yarns undergo meticulous preparation to ensure uniformity and consistency in the subsequent stages.

Weaving

The prepared yarns are then woven together using advanced weaving machines. The weaving process determines the strength and texture of the fabric. In the case of PVC Coated Fabric, a tight and durable weave is essential to provide the necessary foundation for the subsequent coating.

Preparation of Base Fabric

After the weaving process, the base fabric is inspected for any imperfections. It is then cleaned and coated with a primer to enhance its adhesion properties. This step is crucial for ensuring that the PVC coating adheres uniformly to the fabric surface.

PVC Coating Application

The PVC coating is applied to the prepared fabric using advanced coating techniques. This process involves passing the fabric through a series of rollers, where a layer of PVC is evenly spread over the surface. The thickness of the PVC coating is carefully controlled to meet the desired specifications.

Calendering

Calendering is a critical step in the PVC Coated Fabric production process. The coated fabric passes through heated rollers, ensuring that the PVC layer is fused with the base fabric. This enhances the fabric’s overall strength, water resistance, and dimensional stability.

Inspection and Testing

Throughout the entire production process, rigorous quality control measures are implemented. The fabric undergoes thorough inspection and testing for parameters such as tensile strength, tear resistance, and waterproofing capabilities. Any deviations from the quality standards result in corrective actions.

Final Finishing

The finished PVC Coated Fabric is subjected to final finishing processes, which may include additional treatments for UV resistance or anti-microbial properties. This step ensures that the fabric meets or exceeds industry standards for performance and longevity.

Cost-Effectiveness: Unveiling the Long-Term Value of PVC Coated Fabric

Immediate Impact on Maintenance Costs

One of the key advantages of PVC Coated Fabric is its inherent weather resistance. The material is designed to withstand the elements, including harsh sunlight, rain, and temperature fluctuations. Products made from PVC Oxford maintain their integrity and functionality over time, diminishing the need for frequent replacements due to weather-related wear and tear.

Maximizing Product Lifespan

PVC Coated fabric is renowned for its exceptional durability and longevity. The robust nature of the material ensures that products made from PVC Coated have an extended lifespan. This translates into reduced replacement and maintenance costs, ultimately contributing to significant long-term savings.

Reducing Replacement Frequency

While there might be an initial investment in choosing PVC Coated fabric, the long-term cost savings become evident as the material’s durability and resistance to environmental factors lead to a reduction in replacement and maintenance expenses. Over the lifespan of products manufactured with PVC Coated fabric, the overall cost of ownership proves to be more economical than alternatives with shorter lifespans.

Enhanced Overall Cost Efficiency Over Time

PVC Coated fabric is inherently low-maintenance, requiring minimal care to preserve its quality. This characteristic reduces the overall maintenance costs associated with the fabric. Unlike some other materials that demand regular treatments or protective measures, PVC Coated fabric maintains its structural integrity with minimal effort, making it a cost-efficient choice.

Supply Chain Stability: Ensuring Efficiency and Competitive Solutions

Simplifying the Supply Chain

Our factory is dedicated to streamlining the supply chain and optimizing manufacturing processes for enhanced efficiency. This commitment plays a pivotal role in offering competitive prices to our customers. Recognizing the significance of cost-effectiveness throughout the production chain, we strive to provide cost-competitive solutions without compromising on quality.

Cost-Effective Solutions

In a dynamic market, we understand the importance of providing our customers with solutions that are not only cost-competitive but also tailored to their needs. Our customer-centric approach involves a thorough understanding of market demands and a commitment to delivering PVC Coated fabric solutions that align with both quality standards and budget considerations.

Understanding the Importance of Supply Chain Stability

We recognize that cost-effectiveness is a critical factor in the textile industry, and we take proactive measures to ensure that our production methods remain economically viable. By leveraging a well-organized supply chain, we can navigate the intricacies of manufacturing while keeping costs in check. This dedication allows us to offer PVC Coated fabric solutions that are not only of high quality but also competitively priced.

Market Trends and Development: Meeting Demands in a Dynamic Industry

Versatility in Action

Looking ahead, the future seems promising for 420D PVC Coated fabric with a myriad of potential applications. The fabric’s versatility positions it as a frontrunner for use in manufacturing backpacks, tents, and various outdoor gear. Additionally, its water-resistant characteristics make it a viable choice for applications in the production of rainwear, ensuring that users stay dry in adverse weather conditions.

Reliable and Future-Ready

The textile industry is witnessing an increasing demand for high-performance fabrics, driven by consumers seeking products that offer enhanced durability and functionality. This shift in consumer preferences aligns with the growing emphasis on sustainability and longevity. As industries pivot towards incorporating advanced materials, the demand for PVC Coated fabric, especially in the 420D variant, is anticipated to rise significantly.

PVC Coated fabric is well-positioned to meet the evolving demands for high-performance textiles. Its robustness, combined with water-resistant features, caters to the needs of industries requiring durable and weather-resistant materials. Whether it be outdoor equipment, travel accessories, or specialized clothing, PVC Coated fabric has proven itself as a reliable choice.

Customer Testimonials: Raving Reviews for Our PVC Coated Fabric

RQ Textile Company

According to RQ Textiles Inc., a leading manufacturer in the industry, PVC Coated has received positive feedback for its superior durability. Users praise its ability to withstand harsh weather conditions and resistance to wear and tear, making it ideal for outdoor products such as tents and bags.

CARLOS Outdoor Equipment

Carlos Outdoor Gear is a big name in outdoor gear, highlighting the waterproof properties of PVC Coated fabric. Customers are pleased with the fabric’s effective waterproofing capabilities, ensuring their belongings stay dry even in adverse weather conditions.

DEF Fashion Accessories

In the world of fashion accessories, DEF Fashion Accessories celebrates the versatility of PVC Coated fabrics. Customers appreciate the fabric’s ability to retain its shape and color, making it a solid choice for stylish yet functional products like backpacks and wallets.

Conclusion

PVC Coated fabric emerges as a robust and versatile material, seamlessly combining the strength of traditional Oxford fabric with the protective properties of Polyvinyl Chloride (PVC) coating. This amalgamation results in a water-resistant and durable textile, making it a preferred choice for various applications. Renowned for its resilience against the elements, PVC Coated fabric finds extensive use in outdoor gear such as tents and backpacks, as well as industrial applications like tarpaulins and protective covers. Its easy maintenance, resistance to wear and stains, and adaptability for fashion and accessories further underscore its versatility. However, as the industry progresses, a growing emphasis on environmental considerations prompts manufacturers to explore sustainable alternatives and eco-friendly practices. In essence, PVC Coated fabric epitomizes the evolution of textile technology, providing a reliable solution across diverse industries, with ongoing efforts to address environmental concerns shaping its future trajectory.