You may also find:

What is 190T Oxford Fabric?

What is 210D Oxford Fabric?

What is 300D Oxford Fabric?

What is 420D Oxford Fabric?

What is 600D Oxford Fabric?

What is 1200D Oxford Fabric?

What is 1680D Oxford Fabric?

What is PU Coated Fabric?

What is PVC Coated Fabric?

Introduction

The Definition and Composition of 900D Oxford Fabric

900D Oxford fabric is a heavyweight textile crafted with precision, combining high-denier threads to achieve unparalleled strength and durability. Composed of synthetic materials, it embodies a perfect blend of resilience and flexibility.

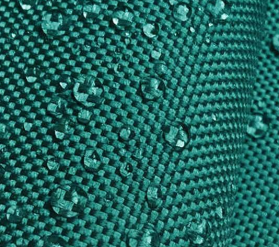

With a robust 900 denier count, this fabric boasts exceptional toughness. Its tight weave enhances resistance to wear and tear, making it a reliable choice for demanding applications. Water resistance, UV protection, and color retention further elevate its appeal.

Application Scenarios of 900D Oxford Fabric

Overview of the Uses of 900D Oxford Fabric in Different Industries

When it comes to outdoor gear, 900D Oxford fabric dominates. Its high denier ensures backpacks, tents and other gear can withstand the rigors of the outdoors.

For travelers looking for a reliable travel companion, luggage and travel accessories crafted from 900D Oxford fabric are the perfect combination of strength and style. The fabric’s ability to withstand frequent handling and exposure to different environments makes it a top choice for the modern adventurer.

In critical areas such as healthcare and emergency response, reliability is critical. 900D Oxford fabric can be used to produce durable covers for medical kits, emergency kits and critical equipment, providing vital protection for professionals in these fields.

Advantages of 900D Oxford Fabric in Various Applications

900D Oxford fabric provides unparalleled strength, essential for tough-use outdoor gear. Whether it’s a backpack, tent or hiking accessory, the fabric’s rugged properties ensure it lasts in challenging terrain.

In industrial environments, constant motion and friction cause wear and tear. The abrasion resistance of 900D Oxford fabric ensures covers and tarps maintain their integrity over extended periods of use.

Our factory’s customization process can tailor fabrics to specific industrial requirements, ensuring covers and tarps meet the unique needs of each application.

For luggage and bags, the fabric offers the perfect combination of style and durability. The high denier ensures the bag retains its shape and structure even during the rigors of travel. At the same time the color fastness of the fabric ensures that the chosen shade remains vibrant over time.

The Powerful Performance of 900D Oxford Fabric

Strength and Durability of 900D Oxford Fabric

At the heart of its strength lies its high denier count of 900. This number represents the density and thickness of the individual yarns of the fabric. The higher the denier, the stronger and more stretchy the fabric is.

Its tight weave and high denier create a protective barrier, minimizing the effects of friction and extending the life of the fabric.

Tear resistance is a key factor, especially in products that are used frequently or are subject to stress. 900D Oxford fabric has excellent tear strength, ensuring it can withstand considerable forces without compromising its integrity.

Waterproofness and Breathability of 900D Oxford Fabric

Our 900D Oxford fabric undergoes a state-of-the-art coating process to enhance its water resistance. This treatment forms a protective barrier on the surface of the fabric, preventing water from penetrating and compromising the integrity of the material.

We use cutting-edge DWR technology to enhance the fabric’s water-repellent properties. This technology ensures water beads away from the surface, keeping the fabric dry even in heavy rain or humidity.

Despite its sturdy construction, the 900D Oxford fabric does a great job of maintaining a comfortable microclimate. Its breathable design promotes air circulation and prevents heat and moisture build-up. This feature is especially important for applications that require long-term wear, such as backpacks, outdoor apparel, and camping gear.

Customizable Services for 900D Oxford Fabric

Understand Customers’ Customization Needs for 900D Oxford Fabric

Through an initial consultation, we gain an in-depth understanding of your project’s specific needs and goals. Whether you’re designing outdoor gear, luggage, or industrial covers, our goal is to make our fabric solutions fit your unique vision.

Participate in the Design and Selection of 900D Oxford Fabric

Our experts will guide you through the material selection process and explain the unique properties of 900D Oxford fabric. We discuss its high denier, synthetic content, and how these attributes give the fabric superior strength and durability.

Once we have a clear understanding of your project needs, our design team develops an initial prototype. These prototypes are a tangible representation of our proposed design concepts, allowing you to visualize and evaluate how the fabric will look and function.

900D Oxford Fabric Production Process

Textile Process

The journey of 900D Oxford fabric begins with the textile process, a fundamental stage that sets the foundation for its strength and resilience. High-denier polyester fibers are carefully selected for their robustness and flexibility. These fibers undergo a sophisticated weaving process, where they are intricately interlaced to form a sturdy and cohesive fabric structure. The 900D denier rating indicates the thickness and density of the individual fibers, ensuring a balance between durability and weight.

Coating Technology

To enhance the fabric’s performance and provide additional features such as water resistance and UV protection, our production process incorporates advanced coating technologies. A specialized coating, often composed of polyurethane or PVC, is applied to the fabric surface. This coating not only reinforces the fabric’s strength but also creates a protective barrier against environmental elements.

Cost Control

Reduce Own Product Replacement and Maintenance Costs

The inherent durability of 900D Oxford fabric significantly extends the lifespan of products made from this material.

Manufacturers benefit from a reduced need for frequent replacements, resulting in substantial long-term cost savings.

The fabric’s abrasion resistance minimizes maintenance costs as the product maintains its structural integrity over a longer period of time.

Reduce Unforeseen Expenses

The sturdy nature of 900D Oxford fabric protects against unexpected expenses due to product failure or quality issues.

Manufacturers can reduce the risks associated with warranty claims or product recalls, thereby contributing to long-term financial stability.

Supply Chain Stability

Procurement of Raw Materials for 900D Oxford Fabric

The foundation of a stable supply chain begins with meticulous raw material procurement. We invest time and resources into partnerships with trusted suppliers to ensure a consistent, high-quality supply of the base materials required for our 900D Oxford fabric. This proactive approach minimizes the risk of disruption and maintains a stable production flow.

Efficient Manufacturing Process of 900D Oxford Fabric

Our commitment to efficiency extends to our manufacturing processes. By implementing lean and optimized production methods, we maximize production while minimizing waste. Not only does this allow us to meet demand in a timely manner, it also contributes to cost-effectiveness, which is reflected in the competitive pricing of our 900D Oxford fabric.

Market trends and Developments

Future Market Trend of 900D Oxford Fabric

The demand for 900D Oxford fabric is growing steadily due to its excellent strength and elasticity. This fabric has become the first choice as industries around the world continue to look for materials that can withstand harsh conditions.

Its high denier and sturdy construction make it suitable for manufacturing products requiring strength and longevity. From outdoor gear like backpacks and tents to industrial applications like protective shields and heavy-duty bags, the potential applications for 900D Oxford are vast.

Industry Demand for High-Performance Fabrics (900D Oxford Fabric)

As the industry demands higher performance and longevity, the demand for high-performance fabrics has surged significantly. Industries such as outdoor recreation, military and industrial manufacturing increasingly rely on materials that can withstand harsh conditions. This shift in demand aligns perfectly with the properties of 900D Oxford fabric, making it a popular solution for manufacturers looking to meet and exceed industry standards.

Considerations and Procurement Recommendations

Choose the 900D Oxford Fabric that Suits Your Product

When opting for 900D Oxford fabric products, it’s essential to consider the intended use. This fabric is ideal for items that require a high level of durability, such as heavy-duty bags, luggage, or outdoor equipment. Ensure that the product specifications align with the demands of your application.

Choose the Right Brand of Oxford Fabric

Reputable brands that prioritize quality and craftsmanship are crucial when purchasing 900D Oxford fabric products. Look for manufacturers with a track record of producing reliable and long-lasting goods, as this reflects on the overall performance of the fabric.

Maintenance Methods for 900D Oxford Fabric

Users should be aware of the fabric’s maintenance requirements. While 900D Oxford fabric is robust, proper care can extend its lifespan. Follow manufacturer guidelines for cleaning and storage to ensure the product retains its integrity over time.

Conclusion

At our core is a commitment to craftsmanship excellence, and every roll of 900D Oxford fabric that leaves our factory is a reflection of precision engineering, cutting-edge technology and the skilled hands of our craftsmen. Our commitment to customization goes beyond just delivering a product; it’s the cornerstone of our philosophy, ensuring the final product fits seamlessly with your unique vision. Impeccable production standards are not an afterthought but a guiding principle integrated into every step, setting a new benchmark for durability, strength and performance. Choosing our facility for your 900D Oxford fabric needs is an exceptional partnership, and we will work side by side with you to strategically contribute to the success of your products.