You may also find:

What is 190T Oxford Fabric?

What is 210D Oxford Fabric?

What is 300D Oxford Fabric?

What is 420D Oxford Fabric?

What is 900D Oxford Fabric?

What is 1200D Oxford Fabric?

What is 1680D Oxford Fabric?

What is PU Coated Fabric?

What is PVC Coated Fabric?

Introduction

In an era where innovation is synonymous with progress, selecting the right materials is paramount to the longevity and success of products. A standout among these materials is the renowned 600D Oxford fabric. Its versatility shines in the creation of bags, backpacks, luggage, tents, and outdoor gear, where durability is non-negotiable. This fabric has become synonymous with reliability, ensuring that products not only meet but exceed the demands of a dynamic market. As industries evolve, 600D Oxford fabric remains at the forefront, weaving a story of resilience and adaptability in the ever-changing landscape of manufacturing and design.

Understanding the Basics

Understanding “600D”: A Measure of Strength

At its core, the term “600D” unveils a critical aspect of fabric composition—the denier or density. This numerical representation signifies the thickness of individual threads interwoven into the fabric, a defining factor in its durability. A higher denier, such as 600D, indicates a thicker and more robust material, imparting strength to the fabric that stands up to the rigors of various applications.

The Intricacies of Oxford Fabric: A Woven Marvel

Distinctive in its construction, Oxford fabric introduces a captivating element to the mix. Characterized by a basketweave pattern, this fabric is a testament to meticulous design and craftsmanship. Typically crafted from a blend of polyester and nylon, Oxford fabric embodies a harmonious marriage of materials, combining the strength of polyester with the flexibility of nylon. This intricate weaving process results in a fabric that not only boasts durability but also offers a visually appealing texture, making it a favored choice in the production of high-quality goods.

Composition of 600D Oxford Fabric

Breaking down the components of 600D Oxford fabric unveils a meticulous fusion of polyester and nylon threads, expertly blended to create a textile marvel. In this intricate dance of materials, polyester contributes its inherent strength, fortifying the fabric, while nylon adds a touch of flexibility, ensuring adaptability to various applications.

The weaving technique employed in the production of 600D Oxford fabric is a testament to the artistry behind its creation. Through a meticulous process, each thread is interwoven with precision, resulting in a fabric that transcends ordinary expectations. This careful craftsmanship yields a robust material renowned for its exceptional strength and remarkable resistance to wear and tear.

Unveiling Superior Quality and Endless Possibilities

600D Oxford fabric stands as a pinnacle in the realm of textile innovation, boasting a myriad of advantages that make it a preferred choice in various industries. Here are some key strengths that set this fabric apart:

Exceptional Durability: Renowned for its robust composition, 600D Oxford fabric is engineered to withstand the trials of everyday use. The high denier count signifies a thicker and more durable material, ensuring longevity and resilience in the face of wear and tear.

Versatility in Applications: The fabric’s versatility knows no bounds. From crafting sturdy bags and backpacks to manufacturing reliable outdoor gear, tents, and luggage, 600D Oxford fabric adapts seamlessly to diverse product lines. Its adaptability makes it a go-to choice for manufacturers seeking reliability across a spectrum of applications.

Resistance to Wear and Tear: The weaving technique employed in its production results in a tight and intricate structure. This not only enhances its overall strength but also provides exceptional resistance to wear and tear. Products made from 600D Oxford fabric maintain their integrity even in challenging environments.

Water-Resistant Coating Options: Many variations of 600D Oxford fabric come equipped with PU (Polyurethane) or PVC (Polyvinyl Chloride) coatings, elevating its performance by adding water-resistant qualities. This makes it an ideal choice for products exposed to the elements, ensuring that they remain functional and visually appealing even in adverse weather conditions.

Versatile Applications of 600D Oxford Fabric

The adaptability of 600D Oxford fabric across these diverse applications underscores its status as a sought-after material. Whether in the great outdoors, during travel, in daily life, or within various industries, this fabric consistently delivers a harmonious blend of strength, reliability, and functionality, making it a versatile choice for manufacturers and consumers alike.

Outdoor Gear

Backpacks and Bags: Whether trekking through rugged landscapes or exploring the urban jungle, backpacks and bags made from 600D Oxford fabric provide reliable storage and durability for adventurers and city dwellers alike.

Tents: The fabric’s resilience makes it a preferred choice for tent manufacturing, offering a weather-resistant shelter for camping enthusiasts and outdoor enthusiasts.

Travel and Luggage

Luggage Manufacturing: 600D Oxford fabric becomes the backbone of travel gear, ensuring that luggage withstands the handling and transport stresses associated with frequent travel.

Apparel and Rainwear

Raincoats and Outerwear: The fabric’s water-resistant properties make it ideal for crafting raincoats and outerwear, providing individuals with protection against unexpected downpours while maintaining comfort.

Customizing Your Vision with 600D Oxford Fabric

Understanding Unique Requirements

At the heart of our customization process lies a dedicated effort to comprehend the distinct requirements of each client. We initiate this journey by engaging in comprehensive discussions to gain insights into the specific needs and preferences of our valued partners. Whether it’s a particular color scheme, a desired thickness, or a specific coating requirement, we prioritize understanding the nuances that make each project unique.

Tailoring Options for Personalized Touch

Once we have a clear understanding of the client’s vision, we present a diverse range of options for customization. Clients have the freedom to choose from an extensive palette of colors, varying thickness levels, and different types of coatings. This flexibility ensures that the final product not only aligns with the client’s specifications but also reflects their brand identity and aesthetic preferences.

Collaborative Efforts for Precision

Our customization process is inherently collaborative. We value the input of our clients at every stage, fostering a partnership that goes beyond transactional exchanges. Through open communication and collaborative efforts, we work hand-in-hand with clients to refine and perfect the chosen specifications. This collaborative approach guarantees the creation of tailored fabrics that not only meet but exceed the expectations of our clients.

Production Process: Crafting Quality from Fiber to Finish

Embarking on a meticulous journey, the production of 600D Oxford fabric is a testament to the commitment to excellence, ensuring quality from fiber selection to the final finish.

Fiber Selection

The journey commences with a crucial decision—the selection of high-quality polyester fibers. This initial step lays the foundation for the fabric’s strength and durability. Careful consideration is given to the composition and characteristics of the fibers, setting the stage for a resilient end product.

Intricate Weaving Techniques

The textile manufacturing phase is where craftsmanship takes center stage. Intricate weaving techniques are employed, creating a fabric that not only meets but exceeds industry standards for strength. Each thread is strategically interlaced, forming a robust structure that can withstand the rigors of diverse applications, from bags to outdoor gear.

Crucial Coating Process

Post-weaving, the fabric undergoes a transformative coating process—a pivotal step that defines its performance attributes. The choice between PU (Polyurethane) and PVC (Polyvinyl Chloride) is made, each offering unique benefits. This coating is not just a surface treatment; it’s a dual-layered shield that enhances water resistance, setting the fabric apart as a reliable choice for outdoor applications.

Dual-Layered Resilience

The dual-layered approach is the secret behind the fabric’s resilience in various conditions. The PU or PVC coating acts as a protective barrier, fortifying the fabric against the elements. This feature is particularly crucial for outdoor products subjected to diverse weather conditions, ensuring longevity and consistent performance.

Quality Control: Ensuring Excellence

Key steps in the manufacturing process are marked by unwavering commitment to quality control. During weaving, meticulous inspections are conducted to guarantee the integrity of each thread and the overall fabric structure. Precision in coating application is paramount, with stringent measures in place to ensure an even and effective distribution. This commitment to quality assurance ensures that every meter of 600D Oxford fabric meets and surpasses the highest standards.

Attributes that Matter: Durability, Tear Resistance, and Water Repellency

Attention to detail at every stage is not just a protocol—it’s the essence of crafting 600D Oxford fabric with exceptional attributes. Durability is ingrained in every thread, tear resistance is fortified through meticulous weaving, and water repellency is perfected in the coating process. These attributes collectively define the fabric’s reliability and performance in diverse applications.

Cost-Effectiveness: Investing Wisely for Long-Term Gains

Understanding Initial Investment

At first glance, the initial investment in 600D Oxford fabric may appear substantial, but it’s essential to view this expenditure as a strategic investment in long-term durability and performance. The quality of the fabric starts to reveal its value proposition from the moment it is integrated into manufacturing processes.

Immediate Impact on Maintenance Costs

One of the immediate advantages of choosing 600D Oxford fabric is its exceptional abrasion resistance. This attribute translates into tangible benefits for manufacturers by significantly reducing maintenance costs. Products crafted from this fabric exhibit remarkable resistance to wear and tear, diminishing the need for frequent repairs or replacements.

Maximizing Product Lifespan

The true brilliance of 600D Oxford fabric lies in its ability to extend the lifespan of products. Items manufactured from this fabric not only withstand the rigors of daily use but continue to deliver top-notch performance over time. This longevity factor is a key contributor to minimizing the overall cost of ownership for manufacturers and end-users alike.

Reducing Replacement Frequency

As products endure less wear and maintain their structural integrity, the need for replacements diminishes. Manufacturers, therefore, benefit from reduced expenses associated with replenishing stocks or responding to warranty claims. This reduction in replacement frequency aligns with sustainable practices, further enhancing the fabric’s cost-effectiveness.

Enhanced Overall Cost Efficiency Over Time

In the grand scheme, the cumulative effect of reduced maintenance costs, prolonged product lifespan, and minimized replacement needs culminates in enhanced overall cost efficiency. While the upfront investment may require careful consideration, the enduring value and cost savings provided by 600D Oxford fabric become increasingly evident as time progresses.

Supply Chain Stability: Streamlining Processes for Competitive Pricing

At the heart of our operations lies an unwavering commitment to optimizing the supply chain and manufacturing processes, a dedication that directly translates into competitive pricing for our clients. By embracing efficiency and simplicity, we ensure that our clients not only receive high-quality 600D Oxford fabric but also benefit from cost-effective solutions.

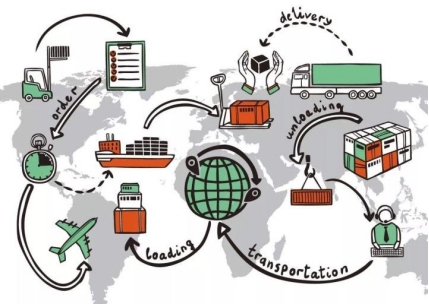

Strategic Supply Chain Simplification

Our commitment to simplifying the supply chain is strategic and all-encompassing. From sourcing raw materials to the final product delivery, we employ streamlined processes. By eliminating unnecessary complexities and embracing modern logistics, we enhance speed, reduce costs, and deliver a seamless experience for our clients.

Lean Manufacturing Principles

Efficient manufacturing is a cornerstone of our strategy. We adhere to lean manufacturing principles, optimizing every stage of production for maximum efficiency. This approach minimizes waste, accelerates production timelines, and allows us to pass on the cost savings to our clients, ensuring competitive pricing without compromising on quality.

Cost-Effectiveness Driving Excellence

Understanding the critical role of cost-effectiveness, our factory operates with a keen focus on maximizing efficiency throughout the production chain. By negotiating favorable terms with suppliers and implementing resource-efficient practices, we create a cost-effective ecosystem. This dedication allows us to consistently offer competitive pricing, providing our clients with a strategic advantage in their markets.

Market Trends and Development: Meeting Demands in a Dynamic Industry

In the ever-evolving landscape of textile industries, a discerning analysis of market trends unveils a resounding demand surge for high-performance fabrics. Amidst this dynamic scenario, 600D Oxford fabric emerges as a frontrunner, asserting its prominence at the forefront of industry preferences.

Versatility in Action

Beyond its robust construction, 600D Oxford fabric excels in seamlessly adapting to diverse applications, from outdoor gear to luggage. Its versatility serves as a valuable asset in an era where customization is paramount, catering to a wide array of industry needs.

Reliable and Future-Ready

In the face of technological shifts and changing consumer preferences, the reliability of 600D Oxford fabric remains unwavering. Its consistent performance and ability to meet evolving demands position it as a stalwart solution for manufacturers navigating a dynamic market. Looking ahead, 600D Oxford fabric is poised to meet the sustained demand for high-performance materials, making it a reliable cornerstone for the textile industry’s dynamic future.

Customer Reviews

The true measure of our success lies in the satisfaction of our clients. Here, we proudly showcase some of the positive feedback we’ve received. Our clients, ranging from importers and distributors to factory owners, consistently applaud our mature technology, faster lead times, and reasonable prices. Their testimonials speak volumes about the trust they place in our 600D Oxford fabric and the value they derive from our products.

“The 600D Oxford fabric from Yirun Textile is a game-changer for our luggage line. Durable, customizable, and always on time – it’s exactly what we need to stay ahead in the market.”-Alex Wong, Luggage Manufacturer

“Our clients love the quality of the 600D Oxford fabric we source from Yirun Textile. It’s a key factor in our products’ success, and the efficient process keeps our inventory flowing smoothly.”-Maria Rodriguez, Bag Importer

“Impressed with the resilience of Yirun Textile’s 600D Oxford fabric. It’s become the backbone of our outdoor gear range. Dependable quality and a breeze to work with.”-Tom Lee, Outdoor Gear Retailer

Conclusion

In conclusion, the journey into the world of 600D Oxford fabric unveils a material that stands at the intersection of durability, versatility, and affordability. From its composition and strengths to its various applications and customizability, 600D Oxford fabric remains a cornerstone in the production of high-quality, long-lasting goods.

As you consider your next venture into products requiring robust and reliable fabric, we invite you to explore the possibilities that 600D Oxford fabric presents. Our factory, with its commitment to customization, advanced production processes, and unwavering quality control, is poised to be your trusted partner in bringing your vision to life.