You may also find:

What is 210D Oxford Fabric?

What is 300D Oxford Fabric?

What is 420D Oxford Fabric?

What is 600D Oxford Fabric?

What is 900D Oxford Fabric?

What is 1200D Oxford Fabric?

What is 1680D Oxford Fabric?

What is PU Coated Fabric?

What is PVC Coated Fabric?

Introduction

In the ever-evolving world of textiles, Oxford fabric emerges as a luminary, celebrated for its exceptional versatility and widespread utility. Within this diverse fabric family, the spotlight shines brightly on 190T Oxford fabric—a true marvel that has seamlessly woven itself into the fabric of various industries. Beyond its utilitarian roots, this remarkable textile has become an indispensable staple, gracing products in realms ranging from outdoor gear to fashion and beyond. Join us as we delve into the intricacies of 190T Oxford fabric, exploring its distinctive qualities and boundless potential that make it an unparalleled choice across a spectrum of applications.

Composition and Characteristics

The Essence of 190T Oxford Fabric

190T Oxford fabric, with its distinct composition, is a true testament to the evolution of textile technology. Comprising high-quality materials, it strikes a perfect balance between density, weight, and strength. The thread count and density contribute to its durability, making it a reliable choice for a multitude of applications.

Key Characteristics

Density and Thread Count: The tightly woven structure of 190T Oxford fabric is a result of a high thread count, ensuring a robust and resilient textile.

Weight and Thickness: Despite its lightweight nature, the fabric boasts an impressive thickness that adds to its overall durability.

Durability and Strength: Renowned for its strength, 190T Oxford fabric can withstand the rigors of everyday use, making it an ideal choice for a range of products.

Unveiling the Versatility: Applications of 190T Oxford Fabric

Outdoor Gear and Equipment

From tents to raincoats, the fabric’s water-resistant and weatherproof properties make it indispensable for outdoor enthusiasts. Its lightweight design ensures that adventurers can carry gear without being weighed down.

Bags and Backpacks

In the realm of fashion and utility, 190T Oxford fabric shines in the creation of bags and backpacks. Its durability ensures that these everyday essentials endure the hustle and bustle of daily life.

Travel and Luggage

Luggage Manufacturing: 190T Oxford fabric becomes the backbone of travel gear, ensuring that luggage withstands the handling and transport stresses associated with frequent travel.

Other Relevant Sectors

Beyond the mentioned applications, 190T Oxford fabric has proven valuable in numerous other sectors, showcasing its adaptability to meet the demands of an ever-evolving market.

Advantages of 190T Oxford Fabric

Lightweight and Durable

One of the standout features of 190T Oxford fabric is its ability to combine lightweight design with exceptional durability. This makes it a top choice for manufacturers seeking materials that offer both comfort and longevity.

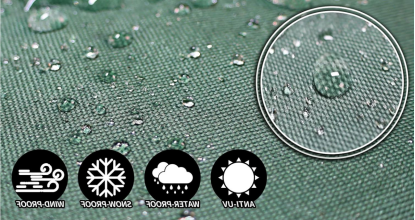

Water-Resistant and Weatherproof

In the unpredictable world of weather, having a fabric that can withstand the elements is crucial. The water-resistant and weatherproof properties of 190T Oxford fabric make it a reliable choice for outdoor applications.

Resistance to Wear and Tear

Constant use can take a toll on fabrics, but 190T Oxford fabric excels in resisting wear and tear. This makes it an ideal choice for products that experience frequent handling or exposure to challenging conditions.

Easy to Clean and Maintain

The fabric’s low-maintenance nature adds to its appeal. Easy to clean and care for, 190T Oxford fabric ensures that products retain their aesthetic appeal over time.

Cost-Effective Solution

Balancing quality with affordability, 190T Oxford fabric provides a cost-effective solution for manufacturers without compromising on the integrity of the end product.

Crafting Your Vision with 190T Oxford Fabric

At the core of our commitment to delivering excellence is a tailored customization process that revolves around understanding and fulfilling the unique requirements of our clients. This journey begins with in-depth conversations, allowing us to delve into the specific needs and preferences of our esteemed partners. Whether it’s a particular color palette, a desired thickness, or a specific coating requirement, our priority is to grasp the intricacies that make each project distinctive.

Tailoring Options for a Personalized Touch

Once we have a clear understanding of our client’s vision, we unfurl a wide array of options for customization. Our clients enjoy the freedom to choose from an extensive palette of colors, varying thickness levels, and different types of coatings. This flexibility ensures that the final product not only aligns with the client’s specifications but also encapsulates their brand identity and resonates with their aesthetic preferences.

Collaborative Efforts for Precision

Our customization process thrives on collaboration. We highly value the input of our clients at every stage, cultivating a partnership that transcends mere transactions. Through open communication and collaborative efforts, we engage with clients to refine and perfect the chosen specifications. This collaborative approach ensures the creation of bespoke fabrics that not only meet but surpass the expectations of our clients.

Behind the Scenes: The Art and Science of Crafting 190T Oxford Fabric

Selection of Raw Materials

The journey commences with a meticulous selection of high-quality raw materials, predominantly polyester fibers. Polyester is chosen for its exceptional strength, durability, and resistance to abrasion, making it an ideal foundation for the robust 190T Oxford fabric.

Weaving

The selected polyester fibers are intricately woven using advanced weaving machines. This step is pivotal in determining the fabric’s structure, density, and overall tensile strength. The weaving process creates a tightly knit foundation, setting the stage for a durable and resilient fabric.

Dyeing

Following weaving, the fabric undergoes the dyeing process. This is a critical stage where the fabric absorbs pigments to achieve the desired color. The versatility of 190T Oxford fabric is highlighted in this step, as a wide spectrum of colors can be achieved, catering to the specific aesthetic preferences of clients.

Coating Application

What sets 190T Oxford fabric apart is the application of coatings, typically Polyurethane (PU) or Polyvinyl Chloride (PVC). These coatings serve multifaceted purposes. They provide water resistance, ensuring the fabric is suitable for outdoor applications. Additionally, they contribute to weatherproofing and enhance overall durability, making the fabric resilient in various conditions.

Calendering

The fabric then undergoes calendering, a process involving the passage through heated rollers. This step not only imparts a smooth finish but also compresses the fabric, enhancing its tensile strength. The calendering process contributes to the fabric’s ability to withstand wear and tear, ensuring a longer lifespan.

Quality Control

Stringent quality control measures are integrated throughout the production process. These measures encompass regular checks for density, thickness, color consistency, and coating uniformity. Any deviations from the specified standards trigger corrective actions, ensuring that each roll of 190T Oxford fabric meets the highest quality benchmarks.

Rolling and Cutting

Once the fabric passes quality control, it is rolled into spools for ease of handling. Depending on client specifications, the fabric is precisely cut into the desired lengths or shapes. This stage is crucial as it tailors the fabric for its intended purpose, whether it be the creation of bags, backpacks, apparel, or other applications.

Final Inspection

The final stage involves a comprehensive inspection to guarantee the fabric is free from defects. This meticulous check ensures that the 190T Oxford fabric delivered to clients adheres to the stringent quality standards set throughout the production process.

The convergence of advanced technology, skilled craftsmanship, and unwavering quality control measures at every stage results in the creation of 190T Oxford fabric – a resilient, versatile, and high-performance textile suited for a myriad of applications.

Cost-Effectiveness: Unveiling the Long-Term Value of 190T Oxford Fabric

Understanding Initial Investment

While the initial investment in 190T Oxford fabric may seem substantial at first glance, it’s imperative to perceive this expenditure as a strategic investment in long-term durability and performance. The quality of the fabric begins to showcase its value proposition the moment it becomes an integral part of manufacturing processes.

Immediate Impact on Maintenance Costs

A standout feature of 190T Oxford fabric is its remarkable abrasion resistance, translating into tangible advantages for manufacturers. By significantly reducing maintenance costs, products crafted from this fabric exhibit exceptional resilience against wear and tear. This characteristic diminishes the need for frequent repairs or replacements, presenting an immediate impact on overall operational expenses.

Maximizing Product Lifespan

The inherent brilliance of 190T Oxford fabric lies in its capability to extend the lifespan of products. Items manufactured from this fabric not only endure the rigors of daily use but continue to deliver top-notch performance over time. This longevity factor becomes a key contributor to minimizing the overall cost of ownership, benefiting both manufacturers and end-users.

Reducing Replacement Frequency

As products experience less wear and maintain their structural integrity, the necessity for replacements diminishes. Manufacturers stand to benefit from reduced expenses associated with replenishing stocks or responding to warranty claims. This reduction in replacement frequency aligns seamlessly with sustainable practices, further enhancing the overall cost-effectiveness of 190T Oxford fabric.

Enhanced Overall Cost Efficiency Over Time

In the broader perspective, the cumulative effect of reduced maintenance costs, prolonged product lifespan, and minimized replacement needs culminates in enhanced overall cost efficiency. While careful consideration may be required for the initial investment, the enduring value and cost savings provided by 190T Oxford fabric become increasingly evident as time progresses. This fabric isn’t just an upfront cost; it’s an investment that pays dividends in sustained performance, reduced operational expenditures, and long-term value.

Supply Chain Stability: Ensuring Efficiency and Competitive Solutions

In our relentless pursuit of excellence, our factory is dedicated to streamlining the supply chain and optimizing manufacturing processes, a commitment that translates into competitive pricing for our clients. Recognizing the pivotal role of cost-effectiveness in the production chain, we strive to offer solutions that are both competitively priced and maintain the highest standards of quality.

Simplifying the Supply Chain

Our commitment to simplifying the supply chain is rooted in the belief that efficiency is the cornerstone of success. By eliminating unnecessary complexities and embracing streamlined processes, we ensure that our clients benefit not only from cost savings but also from a more transparent and responsive supply chain.

Efficiency in Manufacturing

At the heart of our operations lies an unwavering dedication to efficient manufacturing processes. This dedication allows us to achieve economies of scale without compromising the quality of our products. We understand that a well-organized and optimized production flow not only minimizes costs but also reduces lead times, providing our clients with a competitive edge in the market.

Cost-Effective Solutions

Our focus on cost-effectiveness is not a compromise on quality. We believe that delivering competitive pricing should never come at the expense of product excellence. By harnessing innovative approaches, embracing technological advancements, and optimizing every stage of the production process, we have successfully created a synergy between cost-effectiveness and uncompromised quality.

Understanding the Importance of Supply Chain Stability

In today’s dynamic business landscape, supply chain stability is paramount. We recognize that our clients depend on a consistent and reliable flow of materials and products. Through meticulous planning, strategic partnerships, and continuous process improvement, we ensure that our supply chain remains resilient and responsive to market demands.

Market Trends and Development: Meeting Demands in a Dynamic Industry

In the ever-evolving landscape of textile industries, a discerning analysis of market trends unveils a resounding demand surge for high-performance fabrics. Amidst this dynamic scenario, 190T Oxford fabric emerges as a frontrunner, asserting its prominence at the forefront of industry preferences.

Versatility in Action

Beyond its robust construction, 190T Oxford fabric excels in seamlessly adapting to diverse applications, from outdoor gear to luggage. Its versatility serves as a valuable asset in an era where customization is paramount, catering to a wide array of industry needs.

Reliable and Future-Ready

In the face of technological shifts and changing consumer preferences, the reliability of 190T Oxford fabric remains unwavering. Its consistent performance and ability to meet evolving demands position it as a stalwart solution for manufacturers navigating a dynamic market. Looking ahead, 190T Oxford fabric is poised to meet the sustained demand for high-performance materials, making it a reliable cornerstone for the textile industry’s dynamic future.

Customer Testimonials: Raving Reviews for Our 190T Oxford Fabric

Jessica T., Outdoor Gear Manufacturer:

“We’ve been sourcing 190T Oxford fabric from this company for our outdoor gear line, and the quality has been nothing short of exceptional. The fabric’s durability and water-resistant features exceed our expectations. Not only does it withstand the toughest conditions, but the customization options also allow us to create gear that reflects our brand identity. The collaborative approach and prompt delivery have made them our trusted partner in crafting high-performance outdoor products.”

Carlos M., Fashion Accessories Distributor:

“Our fashion accessory line demands materials that not only look good but also stand the test of time. The 190T Oxford fabric from this company has been a game-changer for us. The color options are vibrant and stay true even after extended use. Our products crafted from this fabric not only appeal to fashion-conscious consumers but also provide a level of durability that sets us apart. The personalized touch in the customization process ensures our accessories are unique, and the cost-effectiveness has positively impacted our bottom line.”

Sofia L., Backpack Retailer:

“As a retailer specializing in backpacks, we understand the importance of offering quality products to our customers. The 190T Oxford fabric supplied by this company has been instrumental in elevating the standard of our backpacks. The fabric’s lightweight design combined with its robustness is a winning combination. Our customers appreciate the longevity of the backpacks, and we appreciate the reduced maintenance costs and low replacement frequency. It’s a win-win, and we wouldn’t consider sourcing our fabric from anywhere else.”

These testimonials reflect the satisfaction and confidence that our diverse clientele has placed in our 190T Oxford fabric. We are proud to contribute to the success of our customers by consistently delivering a product that exceeds expectations.

Conclusion

In summary, 190T Oxford fabric stands out as a versatile and high-performance material with applications across various industries. Its durability, waterproof properties, and customization options make it a preferred choice for manufacturers and end-users alike. Choosing to collaborate with us for the production of 190T Oxford fabric ensures access to a superior product backed by mature technology, faster lead times, and competitive pricing. As we continue to explore market trends and advancements, we invite readers to connect with us for customized solutions that elevate the quality and performance of their products.

Feel free to reach out to us to discuss your specific requirements and explore how 190T Oxford fabric can enhance your product offerings. Together, let’s take your products to new heights of quality and performance.