Oxford Fabric for Bags

Oxford fabric is widely esteemed for crafting durable and stylish bags. This robust, woven fabric, often made from polyester or nylon, features a basketweave pattern that lends it substantial strength and resilience. Its versatility allows for various treatments, including waterproofing and UV resistance, making it suitable for everything from casual backpacks to high-end luggage. Oxford fabric’s range in denier count, typically from 210D to 1680D, offers choices in weight and texture, catering to different design needs. Its durability, ease of maintenance, and aesthetic appeal make it a top choice for bag manufacturers seeking a blend of functionality and style.

Table Of Contents For This Page

Explore the comprehensive Table of Contents for this page, your gateway to in-depth insights and information. From the basics of PU coated fabrics to their specialized advantages, each section unfolds a unique aspect of this versatile material. Dive into the topics that pique your interest, and navigate effortlessly through the wealth of knowledge we’ve curated for you. Let this Table of Contents be your guide to understanding the world of PU coated fabrics, their applications, and the numerous benefits they bring to various industries.

General Applications For Oxford Fabric for Bags

Oxford Fabric for Bags is a versatile textile widely used in the production of backpacks, luggage, tents, raincoats and outdoor furniture, to name a few. Its key features include excellent water repellency, making it ideal for outdoor gear, coupled with high durability that ensures reliable protection from the elements and contributes to the longevity of a wide range of products.

Backpack

Luggage

Tent

Raincoat

Outdoor Gear

General Hot Selling Products

Discover our curated selection of Hot Selling Products — a collection handpicked for their popularity, quality, and customer satisfaction. From bestsellers to trending items, these products have captured the attention of our savvy shoppers. Dive into this dynamic lineup and explore what’s making waves in the world of consumer favorites.

Oxford Fabric for Bags

- Component:100%Polyester

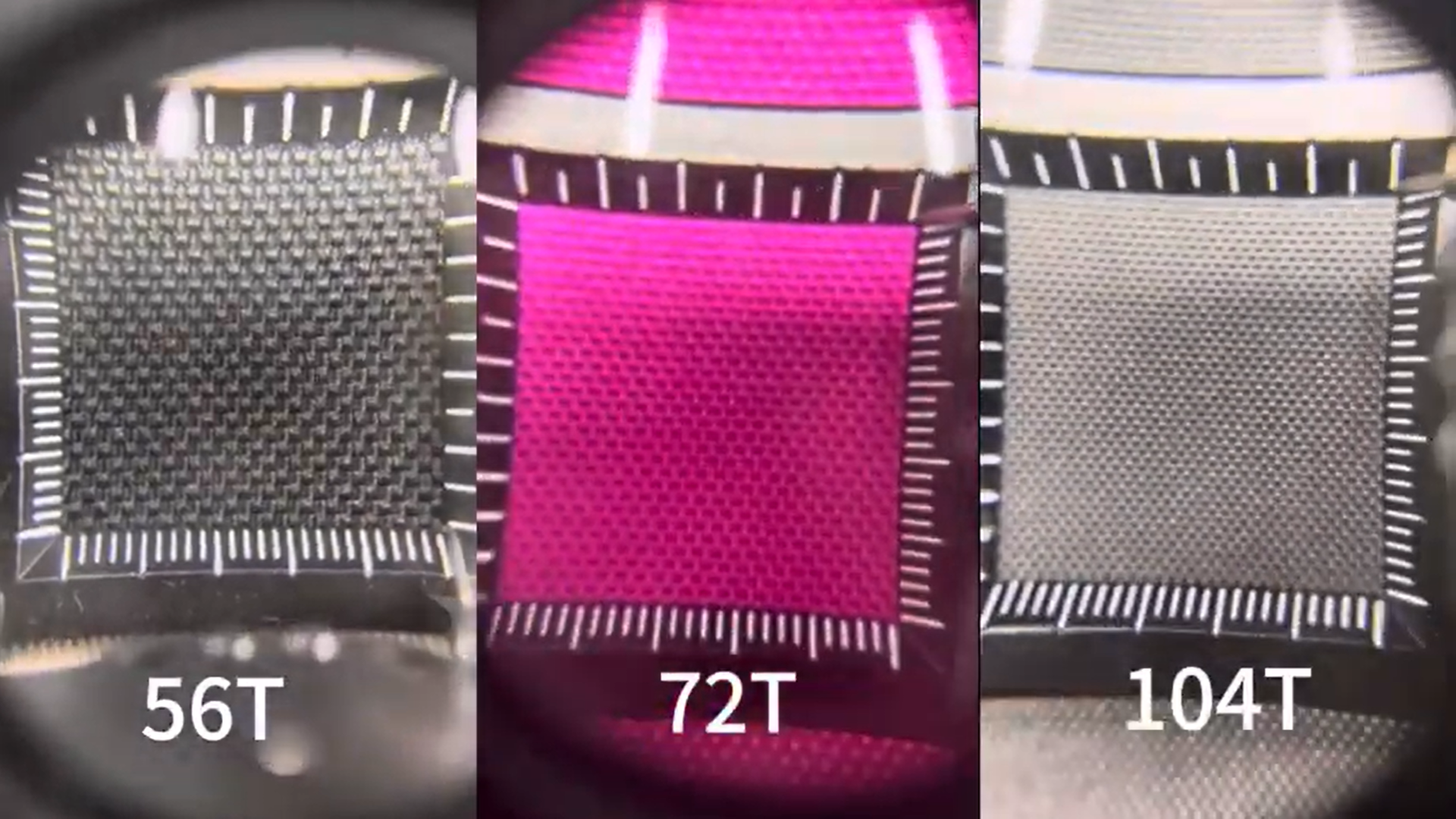

- Yarn Count: 600*600-72T, 900*900

- Weight: 150 gsm to 350 gsm

- Width:150CM

- Coating: PU/ULY/PVC

- Finishing: Waterproof, 1000/3000/5000 mm Water Pressure, Flame-Retardant CPAI-84

- Package: 50m per roll or customized.

Application:Luggage/Tent/Outdoor Goods/Horse Clothing/Raincoat/Backpack/Computer Bag/Beach Chair/Trolley Case

600D Oxford Fabric

- Component:100%Polyester

- Yarn Count: 600*600-72T, 600*600-80T

- Weight: 150 gsm to 240 gsm

- Width:150CM

- Coating: PU/ULY/PVC

- Finishing: Waterproof, 1000/3000/5000 mm Water Pressure, Flame-Retardant CPAI-84

- Package: 50m per roll or customized.

Application:Luggage/Tent/Outdoor Goods/Horse Clothing/Raincoat/Backpack/Computer Bag/Beach Chair/Trolley Case

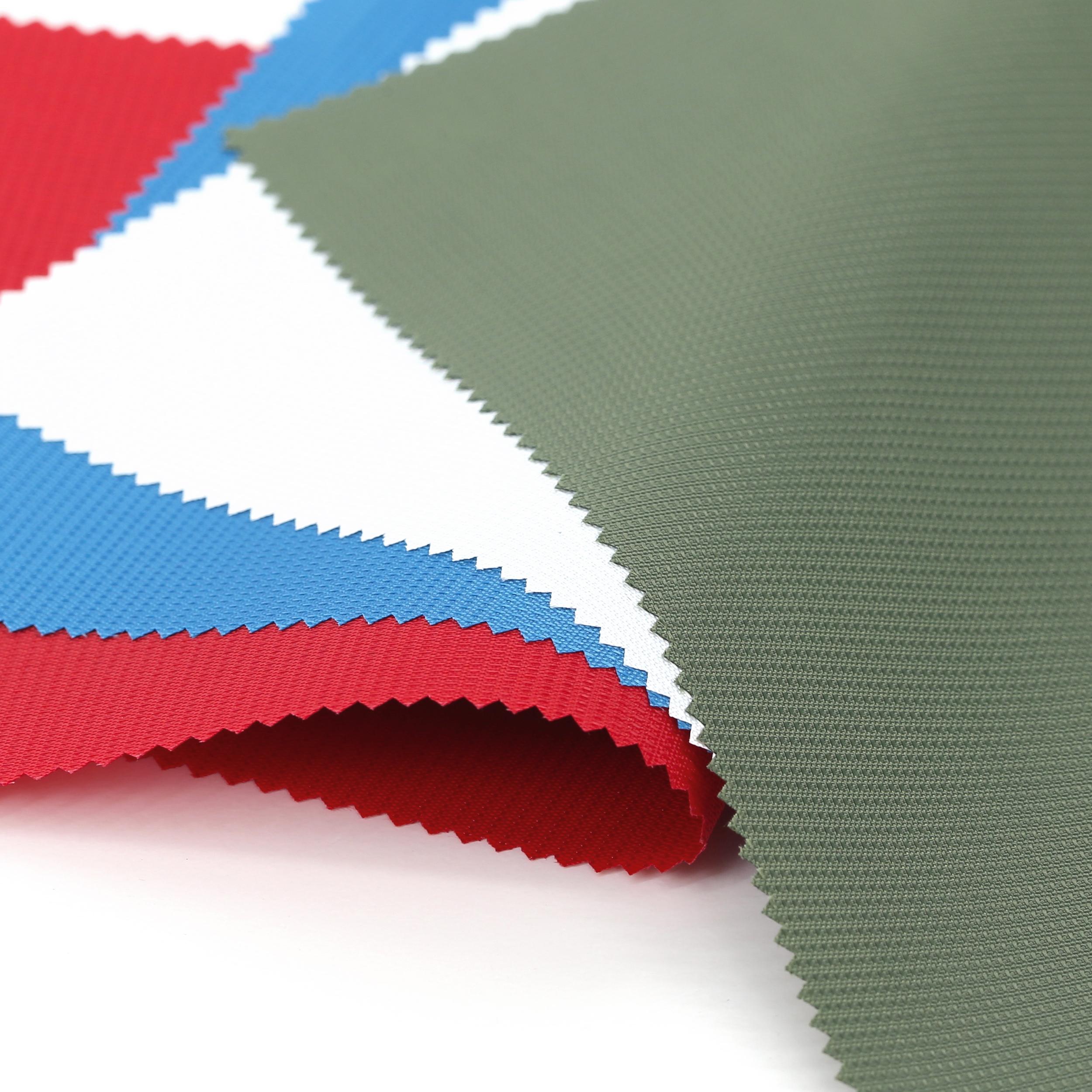

PU Coated Fabric

- Component:100%Polyester

- Yarn Count: 190T, 210D, 300D, 420D, 600D, 900D, 1200D, 1680D

- Weight: 54 gsm to 300 gsm

- Width:150CM

- Coating: PU/ULY/PVC

- Finishing: Waterproof, 1000/3000/5000 mm Water Pressure, Flame-Retardant CPAI-84

- Package: 50m per roll or customized.

Application:Luggage/Tent/Outdoor Goods/Horse Clothing/Raincoat/Backpack/Computer Bag/Beach Chair/Trolley Case

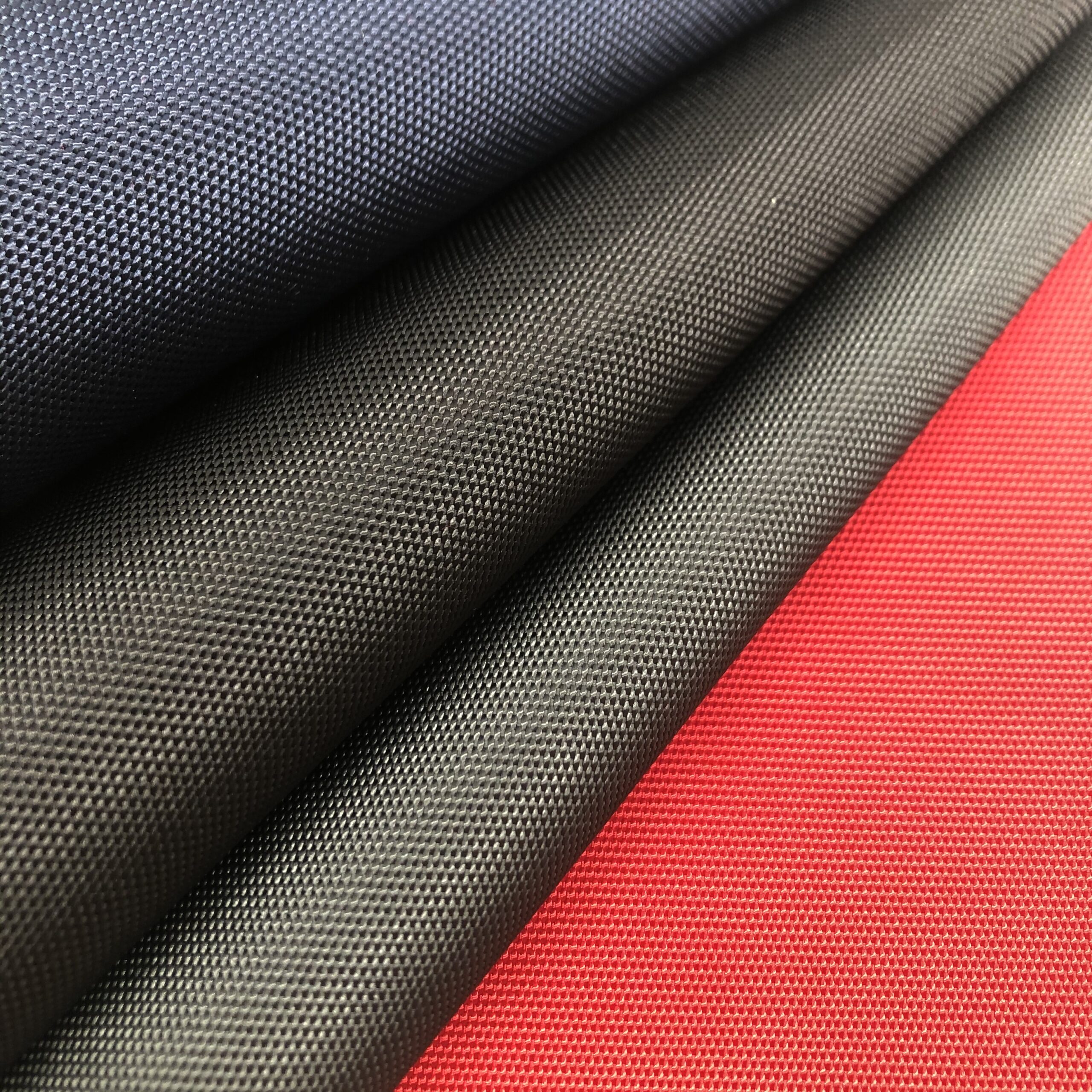

PVC Coated Fabric

- Component:100%Polyester

- Yarn Count: 210D, 300D, 420D, 600D, 900D, 1200D, 1680D

- Weight: 300 gsm to 500 gsm

- Width:150CM

- Coating: PU/ULY/PVC

- Finishing: Waterproof, 1000/3000/5000 mm Water Pressure, Flame-Retardant CPAI-84

- Package: 50m per roll or customized.

Application:Luggage/Tent/Outdoor Goods/Horse Clothing/Raincoat/Backpack/Computer Bag/Beach Chair/Trolley Case

GUCCI Fabric

- Component:100%Polyester

- Yarn Count: 6*6, 7*9, 1000D

- Weight: 290gsm

- Width:150CM

- Coating: PU/ULY/PVC

- Finishing: Waterproof, 1000/3000/5000 mm Water Pressure, Flame-Retardant CPAI-84

- Package: 50m per roll or customized.

Application:Luggage/Tent/Outdoor Goods/Horse Clothing/Raincoat/Backpack/Computer Bag/Beach Chair/Trolley Case

CORD Fabric

- Component:100%Polyester

- Yarn Count: 300*750D, 300*900D

- Weight: 290gsm

- Width:150CM

- Coating: PU/ULY/PVC

- Finishing: Waterproof, 1000/3000/5000 mm Water Pressure, Flame-Retardant CPAI-84

- Package: 50m per roll or customized.

Application:Luggage/Tent/Outdoor Goods/Horse Clothing/Raincoat/Backpack/Computer Bag/Beach Chair/Trolley Case

Jacquard Fabric

- Component:100%Polyester

- Yarn Count: 190T, 210D, 300D, 420D, 600D, 900D, 1200D, 1680D

- Weight: 54 gsm to 500 gsm

- Width:150CM

- Pattern: Customzied.

- Coating: PU/ULY/PVC

- Finishing: Waterproof, 1000/3000/5000 mm Water Pressure, Flame-Retardant CPAI-84

- Package: 50m per roll or customized.

Application:Luggage/Tent/Outdoor Goods/Horse Clothing/Raincoat/Backpack/Computer Bag/Beach Chair/Trolley Case

Snow Fabric/ Cation/Khadi

- Component:100%Polyester

- Yarn Count: 190T, 210D, 300D, 420D, 600D, 900D, 1200D, 1680D

- Weight: 54 gsm to 500 gsm

- Width:150CM

- Pattern: Customzied.

- Coating: PU/ULY/PVC

- Finishing: Waterproof, 1000/3000/5000 mm Water Pressure, Flame-Retardant CPAI-84

- Package: 50m per roll or customized.

Application:Luggage/Tent/Outdoor Goods/Horse Clothing/Raincoat/Backpack/Computer Bag/Beach Chair/Trolley Case

Dobby Fabric/ Rib Check

- Component:100%Polyester

- Yarn Count: 190T, 210D, 300D, 420D, 600D, 900D, 1200D, 1680D

- Weight: 54 gsm to 500 gsm

- Width:150CM

- Pattern: Customzied.

- Coating: PU/ULY/PVC

- Finishing: Waterproof, 1000/3000/5000 mm Water Pressure, Flame-Retardant CPAI-84

- Package: 50m per roll or customized.

Application:Luggage/Tent/Outdoor Goods/Horse Clothing/Raincoat/Backpack/Computer Bag/Beach Chair/Trolley Case

Twill Fabric

- Component:100%Polyester

- Yarn Count: 210D, 300D, 420D, 600D, 900D, 1200D, 1680D

- Weight: 54 gsm to 500 gsm

- Width:150CM

- Pattern: Customzied.

- Coating: PU/ULY/PVC

- Finishing: Waterproof, 1000/3000/5000 mm Water Pressure, Flame-Retardant CPAI-84

- Package: 50m per roll or customized.

Application:Luggage/Tent/Outdoor Goods/Horse Clothing/Raincoat/Backpack/Computer Bag/Beach Chair/Trolley Case

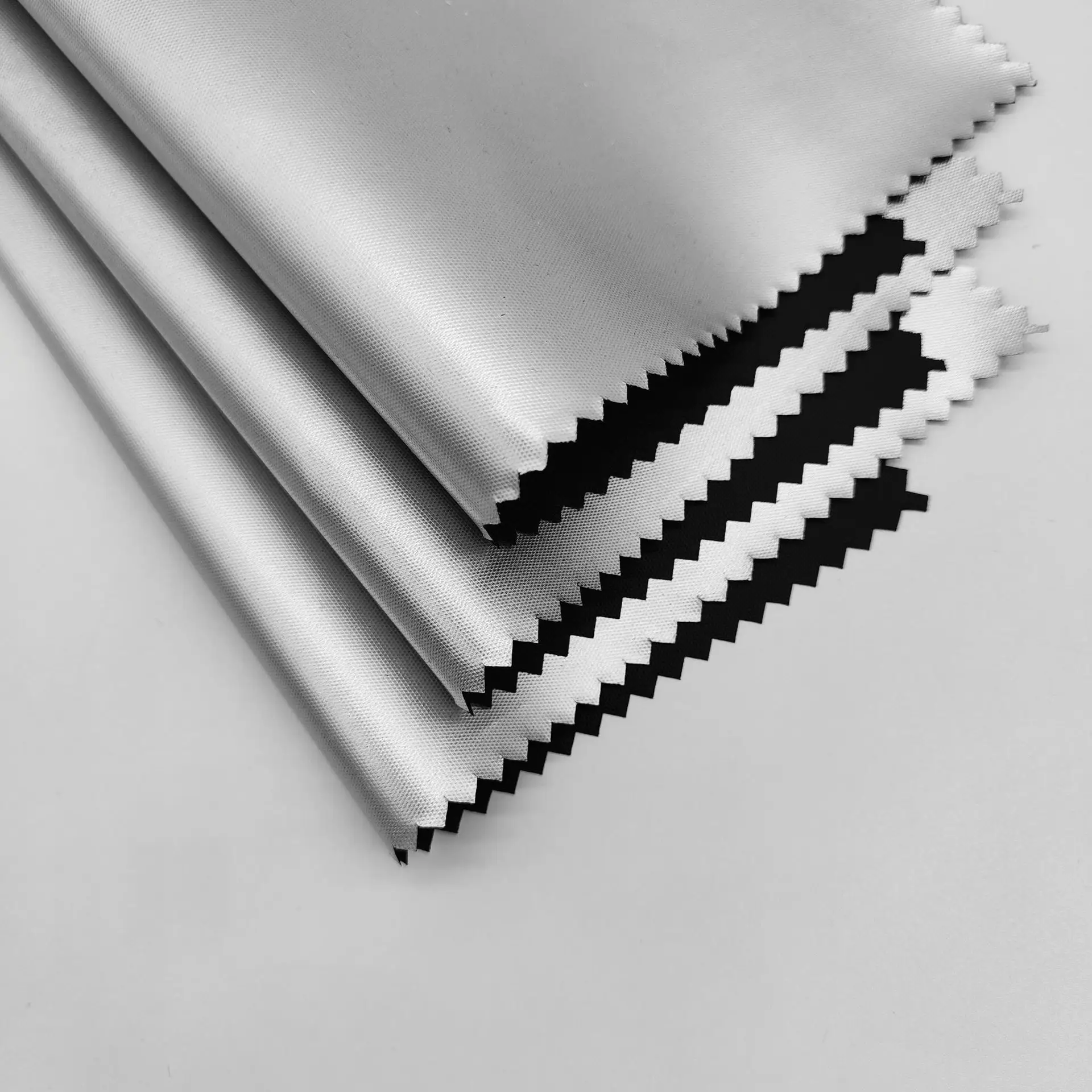

TAFFETA/Lining Fabric

- Component:100%Polyester

- Yarn Count: 190T, 210T

- Weight: 54 gsm to 80gsm

- Width:150CM

- Coating: PU/ULY

- Finishing: Waterproof

- Package: 50m per roll or customized.

Application:Luggage/Tent/Outdoor Goods/Horse Clothing/Raincoat/Backpack/Computer Bag/Beach Chair/Trolley Case

Backpack Fabric

- Component:100%Polyester

- Yarn Count: 190T, 210D, 300D, 420D, 600D, 900D

- Weight: 54 gsm to 300 gsm

- Width:150CM

- Coating: PU/ULY/PVC

- Finishing: Waterproof, 1000/3000/5000 mm Water Pressure, Flame-Retardant CPAI-84

- Package: 50m per roll or customized.

Application:Luggage/Tent/Outdoor Goods/Horse Clothing/Raincoat/Backpack/Computer Bag/Beach Chair/Trolley Case

Luggage Fabric

- Component:100%Polyester

- Yarn Count: 190T, 210D, 300D, 420D, 600D, 900D

- Weight: 54 gsm to 300 gsm

- Width:150CM

- Coating: PU/ULY/PVC

- Finishing: Waterproof, 1000/3000/5000 mm Water Pressure, Flame-Retardant CPAI-84

- Package: 50m per roll or customized.

Application:Luggage/Tent/Outdoor Goods/Horse Clothing/Raincoat/Backpack/Computer Bag/Beach Chair/Trolley Case

Tent Fabric

- Component:100%Polyester

- Yarn Count: 190T, 210D, 420D

- Weight: 54 gsm to 200 gsm

- Width:150CM

- Coating: PU/ULY/PVC

- Finishing: Waterproof, 1000/3000/5000 mm Water Pressure, Flame-Retardant CPAI-84

- Package: 50m per roll or customized.

Application:Luggage/Tent/Outdoor Goods/Horse Clothing/Raincoat/Backpack/Computer Bag/Beach Chair/Trolley Case

Printed Fabric

- Component:100%Polyester

- Yarn Count: 190T, 210D, 420D

- Weight: 54 gsm to 200 gsm

- Width:150CM

- Printing: Customized

- Coating: PU/ULY/PVC

- Finishing: Waterproof, 1000/3000/5000 mm Water Pressure, Flame-Retardant CPAI-84

- Package: 50m per roll or customized.

Application:Luggage/Tent/Outdoor Goods/Horse Clothing/Raincoat/Backpack/Computer Bag/Beach Chair/Trolley Case

Water-Resistant Marvel

In the realm of textile innovations, PU coated fabrics stand out as formidable protectors against water intrusion. The key advantage lies in their exceptional water resistance, making them a preferred choice for various applications. PU coating forms a robust barrier on the fabric’s surface, preventing water from permeating through. This not only keeps the wearer or the product dry in wet conditions but also adds a layer of defense against stains and moisture-related damage. Whether it’s rainwear, outdoor gear, or any application where water resilience is paramount, PU coated fabrics emerge as a reliable solution, seamlessly blending functionality with style.

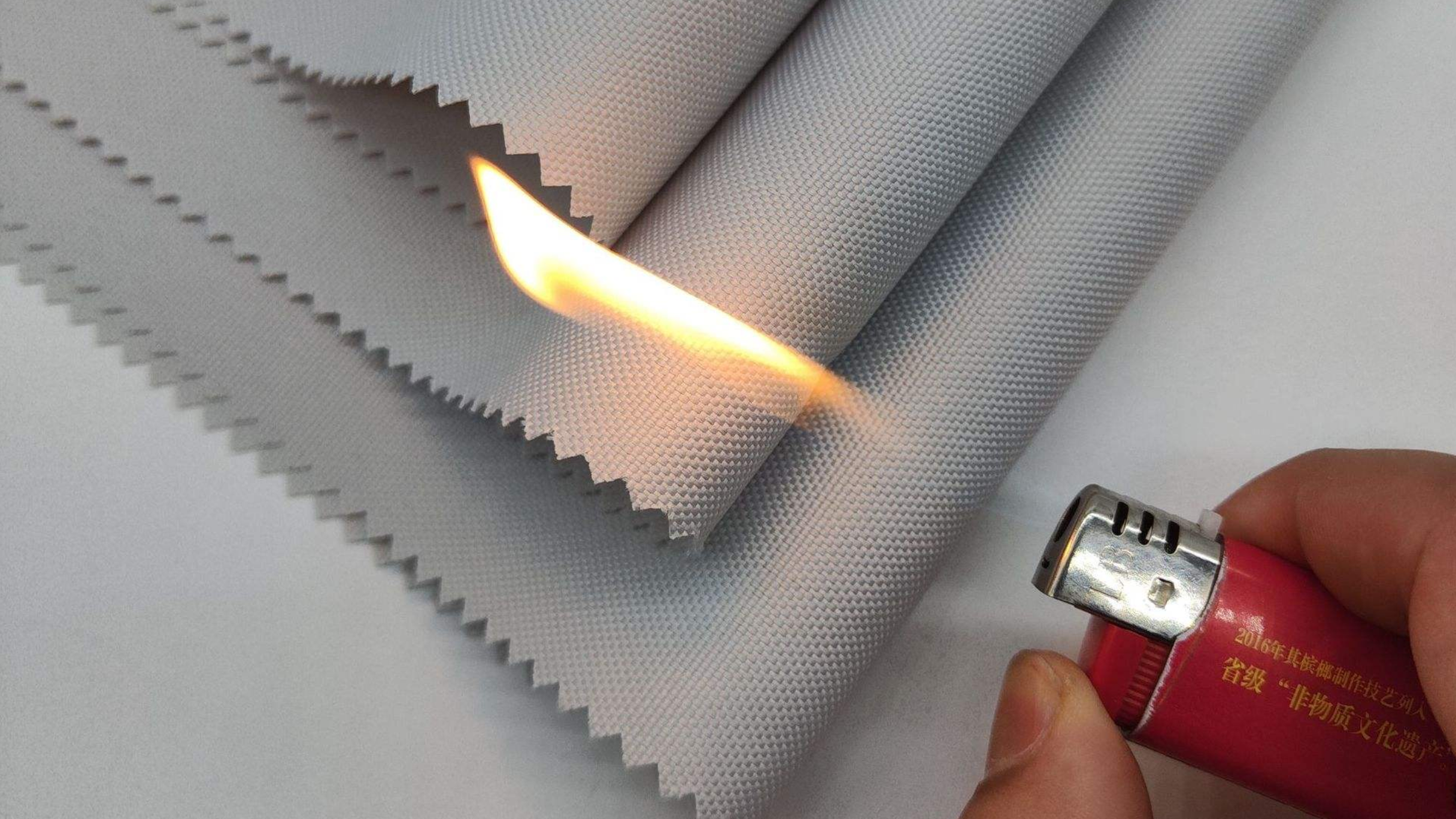

Flame Retardant Guardian

In the realm of textile safety, PU coated fabrics stand out as stalwart defenders against fire hazards. The pivotal advantage lies in their inherent flame retardant properties, making them a preferred choice for applications where fire resistance is paramount. The PU coating creates a robust shield on the fabric’s surface, significantly slowing down the spread of flames and providing crucial moments for safety. Whether it’s protective workwear, industrial applications, or any scenario where fire safety is a priority, PU coated fabrics prove to be a dependable solution, seamlessly merging protective functionality with comfort and style.

Wear-Resistant Warriors

In the dynamic world of textiles, PU coated fabrics emerge as resilient champions against wear and tear. The paramount advantage lies in their exceptional abrasion resistance, making them a top choice for applications demanding durability. The PU coating forms a robust shield on the fabric’s surface, fortifying it against the rigors of daily use. This not only enhances the lifespan of products but also ensures that they maintain their aesthetic appeal over time. Whether it’s outdoor gear, upholstery, or any scenario where longevity is crucial, PU coated fabrics prove to be a steadfast solution, seamlessly combining durability with style.

Oxford Fabric Unveiled

Dive into the heart of textile excellence with ‘Oxford Fabric Unveiled.’ Explore the craftsmanship, versatility, and applications of Oxford fabric in our curated video collection. From production insights to design inspirations, discover the story behind this exceptional textile that defines enduring style and quality.

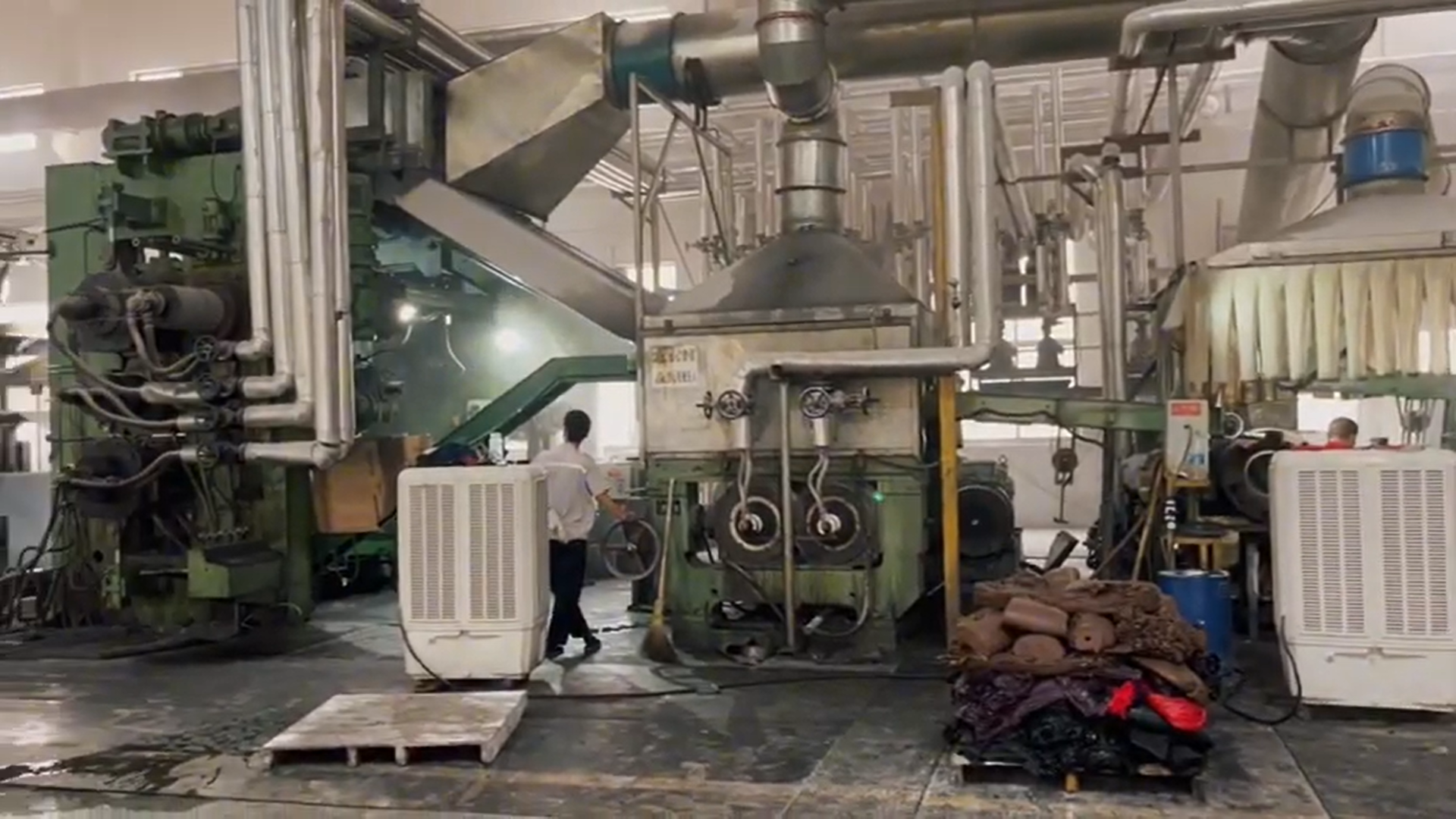

Factory Customization Process

Unlock the world of bespoke manufacturing with our Factory Customization Process section. Delve into the streamlined journey of turning your unique ideas into reality. From concept to creation, we’ll guide you through the intricacies of our customization process, showcasing how we transform visions into tailored products. Explore the possibilities and witness firsthand the power of personalized manufacturing.

Step 1: Consultation

Our journey commences with a comprehensive initial consultation, a pivotal step in crafting luggage that aligns seamlessly with your needs. During this discussion, we delve into the specifics, aiming to grasp not just the practical requirements but the essence of your vision. We seek to understand the nuances of your target market, ensuring that the design and features of your suitcases resonate effectively. Your unique preferences and any distinctive elements you desire for your luggage are central to this conversation. Our goal is not just to meet expectations but to exceed them, creating suitcases that are a perfect reflection of your vision and a standout in the market.

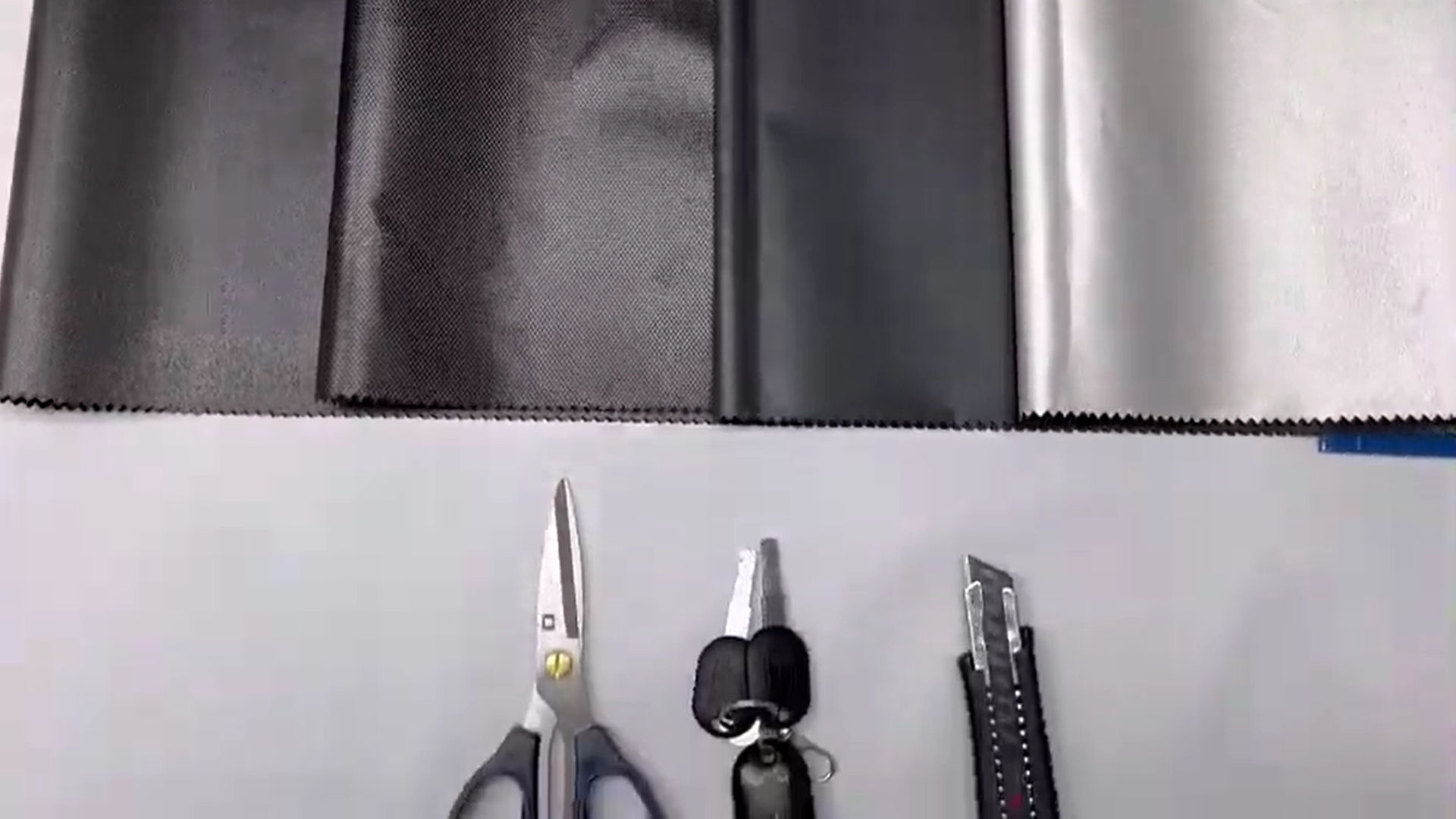

Step 2: Material Selection

Upon gaining a thorough understanding of your unique requirements, our dedicated team takes you through a personalized journey of selecting the perfect polyester Oxford fabric for your project. We delve into the intricacies of the selection process, considering essential factors like the denier value. This parameter, determining the fabric’s thickness and strength, is carefully tailored to meet the specific demands of your venture. Additionally, we provide expert advice on coating options, ensuring they align seamlessly with your project’s goals, whether it be enhancing durability, water resistance, or achieving a particular aesthetic. Our commitment is to empower you with choices that precisely match your expectations and elevate the success of your project.

Step 3: Design and Prototyping

Engaging in a dynamic partnership, our design team works closely with you to bring your vision to life through the creation of prototypes and samples. This collaborative process ensures that every aspect of the final product aligns seamlessly with your expectations. We understand the importance of tactile representation, offering you a hands-on experience with meticulously crafted prototypes. To further personalize your experience, we present an array of color and finish options, empowering you to choose elements that not only meet but exceed your aesthetic preferences. Our commitment is to transform your ideas into tangible, high-quality prototypes that serve as the blueprint for the exceptional final product.

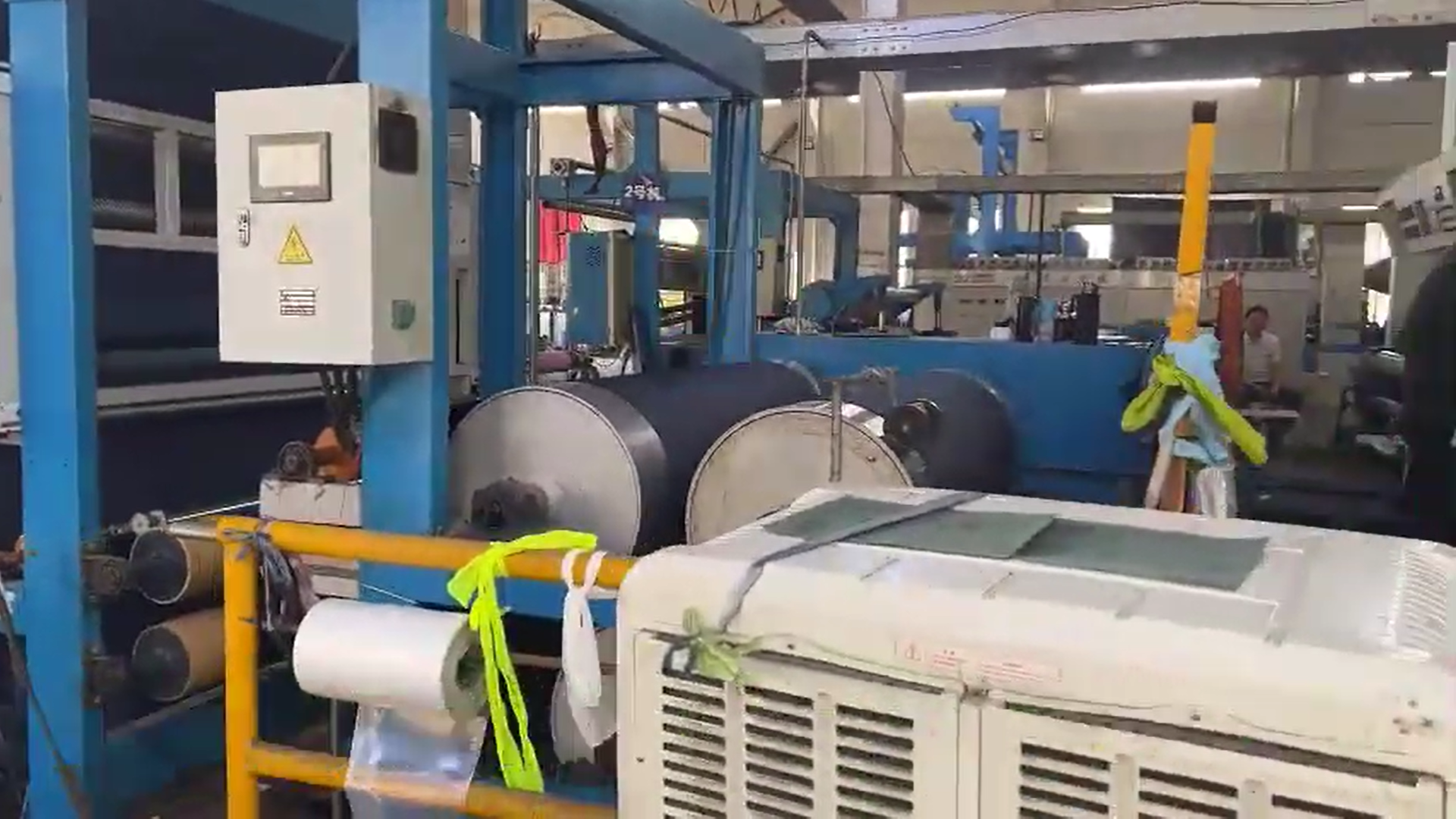

Step 4: Production

Upon receiving your approval for the meticulously crafted prototypes, we seamlessly transition into the full-scale production phase. Leveraging cutting-edge technology and a skilled workforce, we embark on the journey of bringing your vision to life. Our state-of-the-art production facilities ensure precision and efficiency in every step of the process. Expert craftsmanship and attention to detail characterize the creation of the polyester Oxford fabric, a crucial component destined to enhance the durability and aesthetics of your suitcases. As we navigate the complexities of production, our commitment remains unwavering — delivering a product that not only meets but exceeds your expectations, reflecting the culmination of innovation and quality.

Step 5: Quality Control (QC)

At the core of our operations is an unwavering commitment to quality. Rigorous quality control measures stand as the bedrock of our production process, where every meter of fabric undergoes meticulous scrutiny to meet our exacting standards. Our stringent quality assurance protocols encompass a comprehensive examination, ensuring not only durability but also the finest craftsmanship. Through a series of rigorous tests, we verify that each inch of fabric is free from defects, upholding our dedication to delivering products that surpass industry benchmarks. Our emphasis on quality assurance is a testament to our pledge to provide you with polyester Oxford fabric that not only meets but exceeds your expectations in resilience, aesthetics, and performance.

Step 6: Packaging and Delivery

After successfully passing through our rigorous quality control process, the polyester Oxford fabric is handled with utmost care as it undergoes meticulous packaging in preparation for shipment. Our dedicated team ensures that each roll is securely packaged to preserve its integrity during transportation. We take pride in offering reliable and efficient shipping solutions, guaranteeing timely delivery regardless of your location – be it in South East Asia, the Middle East, or South America. Our commitment to a seamless shipping experience underscores our dedication to providing not only top-tier polyester Oxford fabric but also a hassle-free journey from our facilities to your doorstep.

Want to know how to compress lead times?

Production Process

A Brief Self-Nomination, Why Choose Yirun?

Choosing Yirun means opting for excellence and reliability. As a leading provider in the industry, our commitment to quality is unwavering. We bring a wealth of expertise, cutting-edge technology, and a skilled workforce to every project. Our dedication to innovation and precision sets us apart, ensuring that every product surpasses industry standards. From personalized design consultations to meticulous production and stringent quality control, Yirun is a symbol of craftsmanship and integrity. We pride ourselves on timely and efficient deliveries, catering to diverse needs across the globe. Choose Yirun for a partnership built on trust, quality, and a shared commitment to excellence.Choose Yirun for an unparalleled blend of expertise, innovation, and dedication. Your vision, our commitment – together, we build success.

The FAQs About Oxford Fabric for Bags

This section aims to address common questions and provide insightful answers to help you better understand the characteristics, applications, and care of Oxford Fabric for Bags

Q: What is Oxford Fabric for Bags?

A: Oxford fabric for bags is a type of textile material commonly used in the manufacturing of bags and various accessories. It is known for its durability, strength, and water-resistant properties. Oxford fabric is typically made from polyester or a blend of synthetic fibers, and its name often includes a denier rating, such as 600D or 1000D, indicating the thickness and density of the fibers used. The fabric's tight weave pattern contributes to its robustness. Oxford fabric for bags is a popular choice because it can withstand wear and tear, making it suitable for backpacks, luggage, tote bags, and other types of bags that need to endure daily use and adverse weather conditions.

Q: Is Oxford Fabric for Bags waterproof?

A: Oxford Fabric for bags is typically water-resistant rather than completely waterproof. It means that while the fabric can withstand light rain and moisture to some extent, it may not keep the contents of the bag completely dry in heavy downpours or extended exposure to water. However, manufacturers often enhance the water resistance of Oxford Fabric by applying coatings or laminates, such as polyurethane (PU) or polyvinyl chloride (PVC). These treatments make the fabric more effective at repelling water. If you require a fully waterproof bag, you might need to consider additional features like sealed seams and waterproof zippers in addition to the fabric choice.

Q: What is the composition of Oxford Fabric for Bags?

A: Oxford fabric for bags is primarily composed of synthetic materials, typically polyester. This polyester fabric is woven in a unique Oxford weave pattern, characterized by a basketweave texture. The composition includes tightly woven threads that contribute to the fabric's durability and strength, making it ideal for bag construction. In addition to polyester, some variations may incorporate other synthetic fibers or coatings for added features like water resistance or enhanced texture. The specific composition may vary by manufacturer and product type, but the core element remains polyester due to its robustness and versatility, making it a popular choice for bag manufacturing.

Q: What are the key features of Oxford Fabric for Bags?

A: Oxford fabric for bags boasts several key features that make it a popular choice for various applications. Its notable characteristics include exceptional durability, tear resistance, and robustness, ensuring bags can withstand daily wear and tear. Additionally, Oxford fabric can be treated for water resistance, protecting contents from moisture. It offers versatility with different textures and finishes, allowing for customization. This fabric is lightweight, making it suitable for travel and everyday use. Overall, the key features of Oxford fabric for bags encompass durability, water resistance, versatility, and a balance between strength and weight, making it an excellent choice for bag manufacturing.

Q: What are the typical uses of Oxford Fabric for Bags?

A: Oxford fabric is widely employed for crafting bags due to its exceptional qualities. Its durability and water resistance make it a top choice for various bag types. Common uses include backpacks, tote bags, messenger bags, and duffel bags. Oxford fabric's robust nature ensures that bags can withstand the rigors of daily use, making it ideal for school bags, travel bags, and outdoor adventure packs. Its versatility in texture and finish allows for both practical and stylish designs, making it a popular choice in the fashion industry for handbags and accessories. Overall, Oxford fabric enhances the longevity and functionality of bags across a wide range of applications.

Q: Can Oxford Fabric for Bags be used for bags and backpacks?

A: Yes, Oxford Fabric is a versatile material suitable for both bags and backpacks. Its robust composition, often denoted by a denier rating like 600D, ensures durability and resistance to wear and tear, making it ideal for these applications. Oxford Fabric's water-resistant properties, especially when treated with coatings like PU or PVC, provide additional protection for the contents of bags and backpacks during outdoor use or in adverse weather conditions. Its adaptability in terms of texture and finish allows manufacturers to customize the look and feel, making it a popular choice for a wide range of bag and backpack designs.

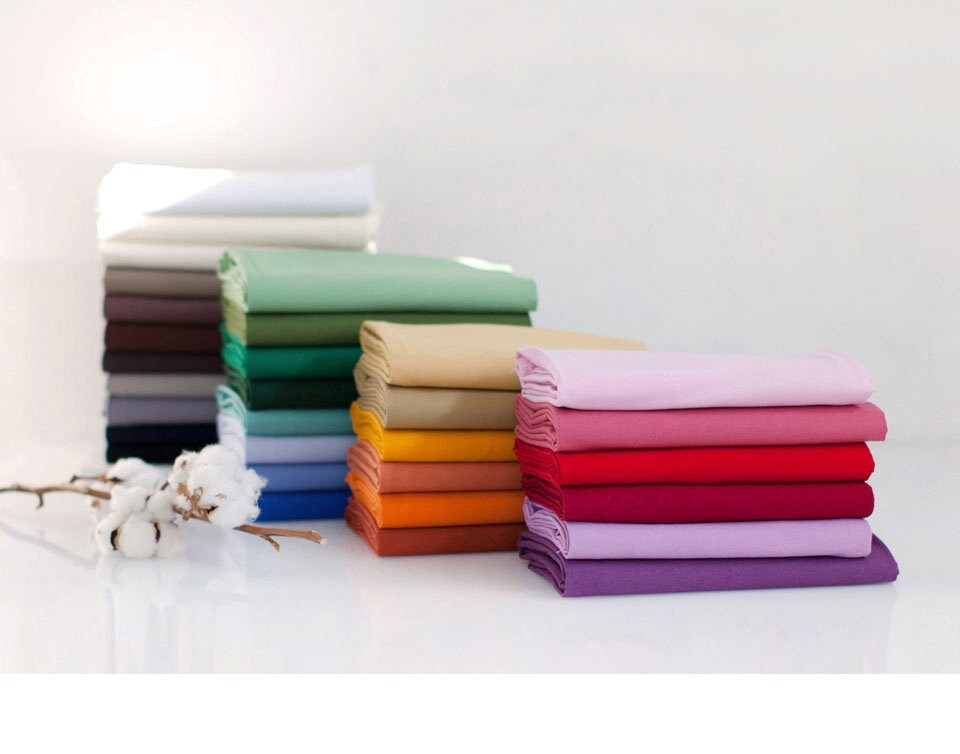

Q: Can the color and pattern of Oxford Fabric for Bags be customized?

A: Yes, the color and pattern of Oxford Fabric for bags can often be customized to meet specific preferences and design requirements. Manufacturers typically offer a range of color options and may provide customization services for patterns, allowing customers to create bags that align with their unique style or brand identity. Customization provides flexibility in designing bags that are not only functional and durable but also visually appealing, making it a popular choice for businesses and individuals looking to create distinctive bags tailored to their needs.

Q: How does Oxford Fabric for Bags compare to other materials like nylon or polyester?

A:

Oxford Fabric for bags, such as 600D Oxford Fabric, offers several advantages compared to other materials like nylon or polyester. Oxford Fabric is known for its exceptional durability and strength, making it a preferred choice for heavy-duty bags. It also boasts good tear resistance and can withstand wear and tear over time.

In comparison to nylon, Oxford Fabric is often more cost-effective while maintaining similar or superior durability. When compared to polyester, Oxford Fabric stands out for its adaptability in various textures and finishes, allowing for a wider range of design options.

Ultimately, the choice between Oxford Fabric and other materials depends on specific needs, but Oxford Fabric is a versatile and reliable choice for bag manufacturing.

The Basic Knowledge About Oxford Fabric for Bags

Embark on a journey into the fundamentals of Oxford Fabric for Bags! In this section, we’ll unravel the basics, shedding light on what makes these coated fabrics unique and versatile. Whether you’re new to the concept or seeking a quick refresher, join us in exploring the essential knowledge surrounding Oxford Fabric for Bags and discover the myriad applications that make them indispensable in today’s industries.

900D Oxford Fabric Manufacturer: Quality, Customization, and Excellence

Behind our 900D oxford fabric’s excellence lies meticulous craftsmanship and advanced coatings. The high denier count ensures its remarkable strength, making it a reliable choice for demanding applications. Our specialized coatings provide unmatched water resistance, while UV protection safeguards against color fading and material weakening. The weaving, coating, and finishing processes are executed with unparalleled precision, resulting in a product that consistently outperforms. In conclusion, our 900D Oxford Fabric isn’t just a textile; it’s a symbol of quality, durability, and high performance. Whether you’re a designer, business owner, or manufacturer, our fabric has the potential to elevate your products to new heights.

What Are Some Innovative Uses of 600D Oxford Fabric?

This article highlights the exceptional qualities and versatile applications of 600D Oxford Fabric with PU or PVC coating, emphasizing its strength, durability, and water resistance. It delves into the fabric’s composition, characteristics, specifications, and quality assurance. The article explores its advantages, including its use in outdoor gear, bags, industrial equipment, and outdoor furniture covers. In conclusion, 600D Oxford Fabric with PU or PVC coating is lauded for its versatility and unwavering quality. It is depicted as an invaluable resource across various industries and a symbol of innovation and excellence. The factory’s commitment to client success and innovative fabric solutions is underscored.

What Are the Applications of 600D Oxford Fabric in Sports and Recreation?

Explore the diverse applications of 600D Oxford fabric in sports and recreation, where its exceptional durability and weather-resistant properties shine. From rugged backpacks for outdoor adventures to reliable tents and sports equipment covers, this versatile fabric plays a pivotal role in enhancing the durability and performance of various outdoor gear and accessories.

The Fabric of Excellence: 420d Oxford Fabric’s Key Attributes and Applications

Explore the remarkable world of 420d Oxford fabric, known for its exceptional durability, water resistance, and versatility. This high-quality textile is favored across industries, from outdoor gear to automotive covers, for its enduring performance and distinctive appearance. Discover how our fabric is redefining excellence in textiles.

How to Choose a Suitable Manufacturer of 300D Oxford Fabric?

Welcome to our Chinese factory’s official blog, where we delve into the world of 300D Oxford fabric manufacturing. In this comprehensive article, we will cover various aspects, including product introduction, applications, and performance characteristics. Additionally, we will shed light on our factory’s customized production process, from initial design to shipment, and highlight our stringent quality control procedures. Whether you’re a seasoned industry professional or new to 300D Oxford fabric, this blog post will provide valuable insights into our capabilities and commitment to quality.

Leading the Industry with Quality 210D Oxford Fabric Manufacturing

We are professional 210D Oxford fabric manufacturer, excels in crafting 210D Oxford fabric, a fusion of strength and innovation. This fabric, with a denier rating of 210, offers exceptional durability and versatility. Its tightly woven structure resists abrasion and tearing, making it ideal for rugged outdoor gear, bags, and apparel. Precision weaving and PU/PVC coatings enhance its performance. Client success stories underscore its transformative impact. Yirun Textile redefines standards in resilience, functionality, and style, catering to diverse needs.

How to Choose a 190T Oxford Fabric Manufacturer?

Experience the pinnacle of fabric excellence with us. Our 190T Oxford fabric embodies unmatched durability, weather resistance, and design versatility. Backed by advanced technology and skilled artisans, each roll reflects precision and quality. Benefit from personalized customization, stringent quality control, and eco-friendly practices. Join our community of satisfied customers across various industries. Choose our Factory for a partnership that goes beyond fabric – it’s a journey to success.

How to Choose PVC Coated Fabric for Bag

Choosing the right PVC coated fabric for a bag involves considering several factors to ensure durability, functionality, and aesthetics. Firstly, assess the fabric’s weight and thickness; heavier fabric offers more durability for heavy-duty bags. Check the waterproofing level to match your bag’s intended use, especially for outdoor or travel bags. Evaluate the fabric’s tear resistance and abrasion resistance to ensure it can withstand regular use. Consider the fabric’s colorfastness and UV resistance to maintain its appearance over time. Lastly, factor in environmental considerations, opting for eco-friendly PVC coatings if sustainability is a priority. Selecting based on these criteria ensures the bag meets both performance and design expectations.

What is PVC Coated Fabric Used For

PVC coated fabric is extensively used for its durability, water resistance, and versatility. Common applications include outdoor gear like tents and awnings, marine products such as boat covers, and protective gear including rainwear and safety equipment. Its robustness also makes it ideal for transportation covers, industrial curtains, and signage due to its ability to withstand harsh conditions and maintain color fidelity. Additionally, PVC coated fabric is favored in manufacturing sports equipment and inflatable products for its strength and flexibility. This wide range of uses demonstrates the material’s adaptability to various demands, offering reliable performance in diverse environments.

How to Choose PU Coated Fabric for Outdoor Gear?

When choosing PU coated fabric for outdoor gear, consider the following factors. First, prioritize waterproofness with a rating of at least 1000mm or higher. Second, look for a balance between waterproofness and breathability to prevent moisture buildup. Third, choose durable fabrics with high tensile strength and tear resistance. Fourth, consider the weight of the fabric, balancing comfort and durability. Fifth, ensure flexibility and stretch for unrestricted movement. Sixth, opt for fabrics with UV resistance to prevent degradation and fading. Seventh, assess whether additional seam sealing is required. Eighth, consider environmental considerations and opt for sustainable or recycled materials. Ninth, set a budget and compare options for overall value. Finally, research reviews and seek recommendations for informed decision-making.

Contact us to get free Samples and Catalogs.

Jeff Fu

+86 15158172046

jeff@ioxfordfabric.com