Introduction

When it comes to versatile and durable materials in the textile industry, 600D Oxford Fabric stands out as a preferred choice for a wide range of applications, from outdoor gear to everyday accessories. A significant aspect of this fabric’s versatility and functionality lies in the various types of coatings applied to it. These coatings are not just additional layers; they play a crucial role in enhancing the fabric’s inherent properties, tailoring it to meet specific requirements and environmental conditions. In this blog, we delve into the world of coatings used on 600D Oxford Fabric – understanding how they transform the fabric and expand its usability. Whether it’s for waterproofing, UV protection, or adding flame retardancy, the right coating can significantly elevate the performance of 600D Oxford Fabric. As we explore these coatings, we’ll discover how they contribute to making this fabric a robust and adaptable choice for numerous applications.

Understanding 600D Oxford Fabric

What is 600D Oxford Fabric?

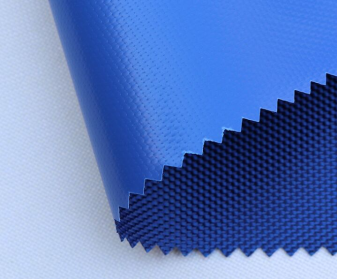

600D Oxford Fabric is a widely-used synthetic material known for its strength and durability. The ‘600D’ refers to the denier, or thickness, of the individual threads used in weaving the fabric, indicating a medium-to-high density. This density contributes to the fabric’s robustness and tear resistance. Made primarily from polyester, 600D Oxford Fabric is valued for its balance of lightness and strength, making it a versatile choice for a variety of applications.

Common Uses and the Need for Protective Coatings

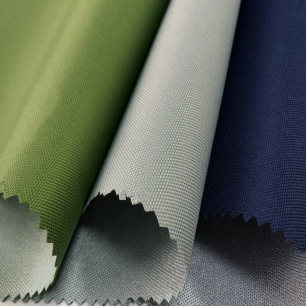

Commonly, 600D Oxford Fabric finds its application in products that require durability and resistance to wear and tear, such as in backpacks, outdoor gear, protective covers, and certain types of apparel. Its usage in these areas often demands additional protection to enhance functionality. This is where coatings come into play. Coatings such as PVC, PU, or silicone are applied to the fabric to augment its natural properties. These coatings can make the fabric waterproof or water-resistant, improve its UV resistance, or even add flame-retardant properties. The choice of coating depends largely on the intended use of the fabric, whether for outdoor camping gear requiring weather resistance or safety equipment needing flame retardancy. This adaptability through various coatings makes 600D Oxford Fabric a highly sought-after material in diverse industries.

Types of Coatings Commonly Used on 600D Oxford Fabric

PVC (Polyvinyl Chloride) Coating

PVC coating on 600D Oxford Fabric is known for its excellent water resistance. This type of coating creates a waterproof barrier, making the fabric highly suitable for outdoor and marine applications where moisture exposure is common. PVC-coated 600D Oxford Fabric is often used in making rain gear, outdoor furniture covers, and bags. Besides water resistance, PVC enhances the fabric’s overall durability, protecting it from wear and tear in demanding environments.

PU (Polyurethane) Coating

Polyurethane or PU coating is another popular choice for 600D Oxford Fabric, known for its flexibility and strength. It significantly improves the fabric’s water resistance while maintaining its breathability, a feature particularly valuable in apparel and camping gear. PU

coating also adds to the fabric’s overall durability, making it tougher and more resilient to physical stresses. Additionally, this type of coating can enhance the aesthetic appeal of the fabric, giving it a more polished and refined finish.

Silicone Coating

Silicone coating is valued for its ability to provide both water resistance and UV protection. This makes 600D Oxford Fabric with silicone coating an excellent choice for outdoor applications, where exposure to sunlight and moisture is frequent. Silicone coating helps in maintaining the color and structural integrity of the fabric, reducing fading and degradation caused by UV rays. It also imparts a smooth, sleek finish to the fabric, contributing to its aesthetic qualities.

Each of these coatings – PVC, PU, and Silicone – plays a significant role in enhancing the functionality and longevity of 600D Oxford Fabric, making it more versatile and suitable for a wide range of applications.

Waterproof and Water-Resistant Coatings

Understanding How These Coatings Work

Waterproof and water-resistant coatings on 600D Oxford Fabric play a crucial role in enhancing the fabric’s utility, especially in outdoor environments. Waterproof coatings create an impermeable barrier on the fabric, preventing water from penetrating through the material under any circumstance. This is achieved through coating processes that include the application of materials like PVC or Polyurethane, which seal the fabric’s pores completely.

In contrast, water-resistant coatings provide a level of protection against water, but to a lesser degree. They are designed to repel water, causing it to bead up and roll off the surface, rather than soaking into the fabric. These coatings, often lighter and more breathable, are applied in a way that keeps the fabric’s pores partially open, allowing for air circulation while still offering protection against light rain and moisture.

Differentiating Between Waterproof and Water-Resistant Coatings

The key difference between waterproof and water-resistant coatings lies in their level of protection against water. Waterproof coatings offer complete protection, making the fabric suitable for use in heavy rain or submerged conditions. These are ideal for gear that needs to stay dry regardless of weather conditions, like camping tents or heavy-duty outdoor covers.

Water-resistant coatings, on the other hand, are suitable for lighter applications where full waterproofing isn’t necessary. They are ideal for everyday items like casual backpacks and outdoor clothing, where breathability and comfort are also important, alongside moderate protection from moisture.

UV Protection and Fade Resistance

Coatings Providing UV Protection

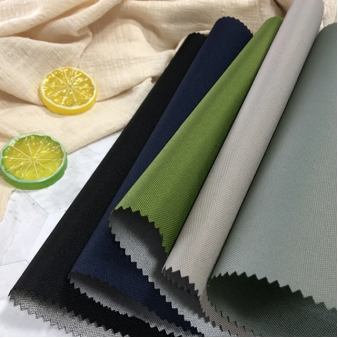

One of the critical enhancements for 600D Oxford Fabric is the application of coatings that offer UV protection. These specialized coatings are designed to shield the fabric from the harmful effects of ultraviolet rays. Exposure to UV light can not only degrade the material but also lead to the fading of colors over time. By applying UV-resistant coatings, the fabric’s longevity is significantly increased, especially when used in outdoor settings where exposure to sunlight is constant. These coatings work by absorbing or reflecting UV rays, thereby minimizing their impact on the fabric.

Maintaining Color Integrity and Preventing Fading

The importance of maintaining color integrity in fabrics, especially those used in visible and aesthetic applications like outdoor furniture and gear, cannot be overstated. UV protective coatings play a vital role in preserving the vibrancy and consistency of colors. They prevent the breakdown of dye molecules that typically occurs under prolonged sun exposure. This feature is particularly beneficial for products that have a strong emphasis on visual appeal and color fidelity. As a result, items made from 600D Oxford Fabric with UV protection coatings remain visually appealing and newer-looking for longer, making them a preferred choice for applications where both durability and appearance are important.

Flame Retardant Coatings

The Role of Flame Retardant Coatings on 600D Oxford Fabric

Flame retardant coatings play a critical role in enhancing the safety features of 600D Oxford Fabric. These specialized coatings are applied to the fabric to reduce its flammability, slowing down the spread of fire and providing crucial extra seconds for safety responses. By chemically treating the fibers or applying a protective layer, these coatings interrupt the combustion process, making the fabric less likely to ignite and more resistant to fire.

Importance in Specific Uses: Camping Gear and Safety Equipment

The application of flame retardant coatings is especially significant in products like camping gear and safety equipment where the risk of fire exposure is higher. In camping scenarios, close proximity to campfires and cooking equipment can pose a fire hazard. Flame retardant-treated fabrics provide an added level of security, ensuring that tents, sleeping bags, and other camping accessories are safer in the event of accidental fire exposure. Similarly, in safety equipment used in industrial settings or by emergency responders, flame retardant coatings are crucial. They help in minimizing fire-related risks, ensuring that protective gear like tarps, covers, and emergency shelters can better withstand high-heat situations. The use of flame retardant coatings on 600D Oxford Fabric in these contexts underscores a commitment to safety without compromising on the fabric’s inherent qualities of durability and flexibility.

Environmental and Health Considerations

Addressing Concerns Related to Coatings

When it comes to the coatings used on 600D Oxford Fabric, it’s important to consider the environmental and health implications. Certain chemical treatments used for waterproofing or enhancing durability can raise concerns, especially if they involve substances like phthalates or heavy metals. These chemicals can be harmful if they leach into the environment or come into prolonged contact with human skin. Therefore, understanding the composition of these coatings is crucial for both manufacturers and consumers.

Eco-Friendly and Non-Toxic Options

In response to these concerns, there has been a significant shift towards eco-friendly and non-toxic coating options. Innovations in fabric technology have led to the development of coatings that are not only effective but also environmentally responsible. These include water-based polyurethane (PU) coatings and silicone treatments, which provide the desired fabric properties without the harmful side effects of traditional coatings. These alternatives are not only safer for the environment but also for the health of the end-users, ensuring that the fabric remains a safe choice for a variety of applications. By opting for 600D Oxford Fabric with such eco-conscious coatings, manufacturers and consumers can contribute to a healthier ecosystem and safer product usage.

Choosing the Right Coating for Your Needs

Choosing the right coating for 600D Oxford Fabric is crucial to ensure it meets the specific demands of its intended use. Here are some guidelines to help you make an informed decision:

Assess the End-Use Requirements: The primary factor in selecting a coating is the intended use of the fabric. For outdoor gear like tents or backpacks, a waterproof or water-resistant coating is essential. PVC or PU coatings are commonly used for these purposes, offering excellent water repellency.

Consider Durability Needs: If the fabric will undergo heavy use or be exposed to rough conditions, durability is key. A thicker PVC coating can provide added strength and abrasion resistance, making it suitable for heavy-duty applications.

UV Protection and Color Longevity: For items that will be frequently exposed to sunlight, such as outdoor furniture covers, opt for a UV-resistant coating. This helps in maintaining the color vibrancy and integrity of the fabric over time.

Flame Retardancy for Safety: In applications where fire safety is a concern, such as in certain camping or industrial gear, a flame-retardant coating is necessary. Ensure that the coating meets the relevant safety standards for your product’s specific use.

Environmental and Health Considerations: Be aware of the environmental and health impact of the coatings. Opt for eco-friendly and non-toxic options where available, especially for products like children’s gear or clothing.

Consult with Experts: If unsure, consult with coating experts or fabric manufacturers. They can provide valuable insights and recommendations based on their experience and the latest technological advancements in fabric coatings.

By considering these factors, you can select a coating for 600D Oxford Fabric that not only enhances its functionality but also aligns with the specific needs of your product, ensuring optimal performance and customer satisfaction.

Conclusion and Call to Action

In conclusion, selecting the appropriate coating for 600D Oxford Fabric is crucial to ensure that it meets the specific needs and demands of its intended application. The right coating can significantly enhance the fabric’s durability, water resistance, UV protection, and even flame retardancy. Whether for outdoor gear, safety equipment, or everyday items, the coating chosen directly impacts the fabric’s performance, longevity, and safety. Understanding the different types of coatings and their unique benefits allows for a more informed decision, tailoring the fabric to specific environmental and functional requirements.

We invite you to explore the possibilities that the right coating on 600D Oxford Fabric can offer. If you are looking for specific properties or have particular requirements for your fabric needs, our team is here to provide expert advice and tailored solutions. For more detailed information, to discuss your unique fabric requirements, or to make inquiries about our 600D Oxford Fabric options, please don’t hesitate to contact us. Let us assist you in finding the perfect coated 600D Oxford Fabric solution that aligns with your project’s needs.