Introduction

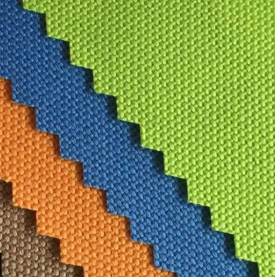

Oxford fabric, when combined with PU (Polyurethane) or PVC (Polyvinyl Chloride) coating, becomes a powerhouse of performance, making it the ideal choice for manufacturing a wide range of outdoor products, with tent fabric being a prime application.Oxford fabric is a woven textile known for its incredible versatility and durability. It is originally named after the prestigious University of Oxford but has found its way into numerous applications due to its robust nature.What truly sets our Oxford fabric apart is the advanced coating technology we employ. The addition of PU or PVC coatings takes this fabric to the next level, enhancing its inherent qualities to match the demanding requirements of outdoor applications.

Applications of Oxford Fabrics

Tent Manufacturing: Oxford fabrics are particularly popular in the production of tents. Their combination of durability and waterproofing is essential for providing shelter in outdoor environments. Whether it’s a family camping trip or a mountaineering expedition, these fabrics are up to the task. They can endure harsh weather conditions, from heavy rain to strong winds, ensuring the safety and comfort of those inside.

Raincoats and Outdoor Clothing: Oxford fabrics are also used in the creation of high-quality raincoats and outdoor clothing. These materials provide excellent protection against rain and wind, keeping wearers dry and comfortable during inclement weather. Whether it’s a lightweight jacket for a hike or a heavy-duty raincoat for extreme conditions, Oxford fabrics perform admirably.

Backpacks and Luggage: Oxford fabrics are a favorite choice for manufacturers of backpacks, luggage, and travel bags. Their durability and resistance to abrasion ensure that these products can withstand the rigors of travel. The lightweight nature of the fabric is particularly advantageous for those on the move, as it allows them to carry their belongings without adding unnecessary weight.

Outdoor Gear: Beyond tents, clothing, and bags, Oxford fabrics are also used in various outdoor gear such as tarps, ground cloths, and even outdoor furniture. Their versatility makes them an ideal choice for any product that needs to withstand outdoor conditions.

Performance Attributes

Wear resistance and durability

Oxford fabric is known for its excellent wear resistance. This makes them perfect for tent making. The fabric can withstand the rigors of outdoor use, including contact with rough surfaces like rocks and branches, without showing signs of wear. Even in harsh conditions, Oxford fabric maintains its structural integrity, ensuring your tent is long-lasting.

At the same time their durability is a result of the inherent strength of the fabric and the reinforcement of the PU or PVC coating. This combination of toughness and elasticity ensures your tent will last for years, even with regular use in challenging conditions. You can be confident that your investment in an Oxford fabric tent will provide long-term value.

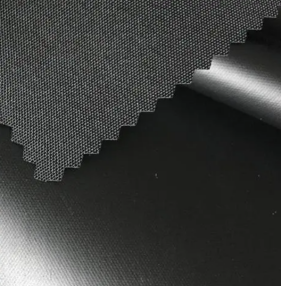

Waterproofing

The PU or PVC coating takes the inherent water-resistant properties of Oxford fabric to the next level. It provides an effective barrier against moisture, making the fabric completely waterproof. This means that even during heavy rain or in damp environments, your tent will keep you dry and comfortable. The waterproofing feature ensures that you can enjoy the great outdoors without worrying about leaks or water seeping in.

Lightweight

Despite their remarkable durability and strength, Oxford fabrics remain surprisingly lightweight. This is a significant advantage for tent manufacturing, as it makes the tents easy to transport and set up. The lightweight nature of the fabric ensures that you can carry your tent with ease, whether you’re backpacking to a remote campsite or setting up a base at a music festival. It strikes the perfect balance between sturdiness and portability, making it an excellent choice for outdoor enthusiasts.

Factory Customization Process

Customer Needs Analysis

The process begins with a comprehensive analysis of your specific needs. Our experienced team of experts collaborates with you to understand your project requirements in detail. This includes factors such as the type of product you are manufacturing, the desired fabric specifications, coating preferences (PU or PVC), color choices, and any other unique features you may require.

Custom Design and Sample Production

Once we have a clear understanding of your needs, our design team creates customized design plans. These plans take into account all your requirements and preferences. We then produce sample fabric pieces based on these designs. These samples allow you to physically inspect the fabric and ensure it meets your expectations before we proceed with full-scale production.

Order Planning

After you approve the samples, we move on to the order planning stage. We determine the exact quantities you require and establish a production schedule. Our efficient production planning ensures that you receive your customized Oxford fabric in a timely manner.

Throughout this customization process, open communication with our clients is vital. We keep you informed at every stage, from design to sample approval to final production. This collaborative approach ensures that the Oxford fabric we produce precisely aligns with your requirements, resulting in a product that not only meets but exceeds your expectations.

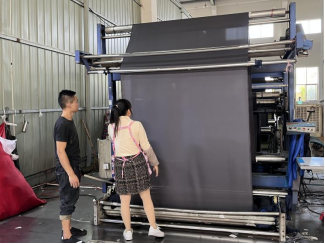

Production Process

Material Selection and Preparation

Fabric Inspection: Skilled technicians meticulously inspect the fabric rolls for any imperfections or defects. Only the finest quality material passes this stage.

Pre-Treatment: The selected fabric is pre-treated to remove any impurities or contaminants. This process ensures that the fabric is clean and ready to accept the PU or PVC coating.

Printing and Coating

Coating Application: The fabric is passed through machines where the PU or PVC coating is evenly applied to both sides. This coating enhances the fabric’s waterproofing and durability, making it suitable for a wide range of outdoor applications.

Printing: Some applications may require specific designs or patterns on the fabric. Our advanced printing technology ensures that the fabric is customized to meet your unique needs.

Quality Control

In-Process Inspection: Every step of the production process is subject to in-process inspections. This continuous monitoring helps us catch and rectify any issues in real time.

Final Quality Check: Before products are packaged and prepared for shipping, they undergo a final quality check to ensure that they meet our stringent standards.

Shipping Process

Packaging and Labeling

We take great care in packaging and labeling your orders to ensure that they arrive in the best possible condition. Each product is meticulously folded, sealed, and prepared for shipping. We use high-quality packaging materials to protect your items during transit.

Logistics

Our commitment to delivering your products on time is unwavering. We collaborate with a network of trusted logistics partners who specialize in the transportation of our goods. These partners are well-versed in handling and delivering our products to various destinations. They understand the importance of timeliness and the need to handle your orders with care.

Delivery Time

We understand that prompt delivery is a key factor in your satisfaction. Our streamlined processes, from order placement to production, allow us to meet agreed-upon delivery times consistently. We keep you informed at every stage of the shipping process and provide tracking information to ensure you know when to expect your order.

Quality Control Process (QC)

Quality Inspection Standards

At our factory, maintaining stringent quality control standards is of utmost importance. We have a comprehensive set of quality inspection criteria that each product must meet before it is approved for shipment. These criteria encompass various aspects, including:

Fabric integrity: We examine the fabric for any defects, irregularities, or imperfections that may affect its performance.

Coating uniformity: The PU or PVC coating is checked for consistency to ensure the waterproof and durability attributes are evenly applied.

Seam strength: Stitching quality is assessed to verify that seams are strong and resilient.

Dimensional accuracy: We measure and verify the precise dimensions and sizes of each product to meet your specifications.

QC Steps

Our quality control process involves several key steps to ensure that our products meet the highest standards:

Initial Inspection: The fabric is inspected before the coating process begins to identify any defects or imperfections in the base material.

In-Process Inspection: At various stages during production, our skilled quality control personnel examine the fabric to verify that it is meeting our rigorous standards.

Final Inspection: After production is complete, a final inspection is carried out to confirm that the product complies with our quality criteria.

Random Sampling: We perform random sampling to maintain consistency and verify that every batch meets the quality benchmarks.

Product Quality Assurance

We take great pride in the quality of our products. Our commitment to quality extends beyond our QC process and includes quality assurance through the selection of high-grade materials, meticulous production, and the use of top-notch machinery and technology. We stand behind the quality of our Oxford fabrics and guarantee that they will meet your expectations.

Our Competitive Advantages

Mature Technology

Our factory boasts a legacy of excellence in textile manufacturing. With years of experience in the industry, we have mastered the art of fabric production. Our technical know-how is continually updated to keep pace with the latest innovations in fabric technology. This means you can trust that the Oxford fabrics we produce are of the highest quality, incorporating the latest advancements in material science.

Faster Lead Time

We understand the value of time in the world of manufacturing. Our streamlined processes and efficient workflows allow us to offer some of the industry’s shortest lead times. We prioritize timely delivery without compromising on the quality of your orders. Our commitment to punctuality has made us a reliable partner for customers who need to meet strict production schedules and deadlines.

Reasonable Pricing

While we pride ourselves on delivering top-notch quality, we also recognize the importance of competitive pricing. Our commitment to cost-effectiveness means you get premium Oxford fabrics at a price that doesn’t break the bank. We maintain a balance between quality and affordability, ensuring that you receive exceptional value for your investment. Our transparent pricing structure and flexibility in meeting your budget requirements set us apart from the competition.

Our Market and Customers

Main Market Regions

Our Oxford fabrics have found a strong foothold in several key regions, including:

South East Asia: With its diverse climate and outdoor recreational activities, South East Asia has embraced our Oxford fabrics for manufacturing various outdoor products.

Middle East: The arid and unpredictable weather conditions of the Middle East make our waterproof and durable Oxford fabrics essential for outdoor gear.

South America: From the Andes to the Amazon rainforest, South America’s diverse terrain demands reliable outdoor equipment, which our fabrics deliver.

Target Customer Base

Our dedication to quality, timely deliveries, and competitive pricing has earned us a diverse and loyal customer base, including:

Importers: Importers appreciate the consistency and quality of our Oxford fabrics as they supply materials to various industries and brands.

Distributors: Distributors choose our fabrics for their dependability, ensuring the products they sell meet high standards.

Factory Owners: Factory owners rely on our fabrics to enhance the durability and functionality of their outdoor products.

Customer Priorities

We understand that our customers value specific factors when choosing a supplier:

Price: Our competitive pricing allows customers to maximize their value for money.

Quality: Quality is the foundation of our products, and our customers can depend on us for materials that meet rigorous standards.

Lead Time: In a fast-paced market, we excel in providing products on time, ensuring production schedules are met.

Conclusion

In a world where outdoor gear and equipment must withstand the rigors of nature, the fabrics you choose can make all the difference. Oxford fabrics with PU or PVC coating are the gold standard when it comes to making tents, rain jackets, backpacks, luggage and more, combining strength, durability and water resistance.

At our factory, we take great pride in our commitment to producing the highest quality Oxford fabrics. We prioritize quality and it shows in every yard of material we produce. Our commitment to excellence extends to every step of the manufacturing process, from material selection to printing, coating, cutting, stitching and rigorous quality control.

Our market coverage spans Southeast Asia, the Middle East and South America, serving importers, distributors and factory owners. We recognize that our customers prioritize price, quality and delivery time. That’s why we’re committed to exceeding their expectations and delivering products that can withstand the most demanding environments.

So, when you choose us, you don’t just choose the fabric; you choose us. Choose quality, choose us.