You may also find:

What is 190T Oxford Fabric?

What is 210D Oxford Fabric?

What is 420D Oxford Fabric?

What is 600D Oxford Fabric?

What is 900D Oxford Fabric?

What is 1200D Oxford Fabric?

What is 1680D Oxford Fabric?

What is PU Coated Fabric?

What is PVC Coated Fabric?

Introduction

In the ever-evolving landscape of textiles, certain fabrics emerge as industry frontrunners, seamlessly blending durability, versatility, and innovation. At the forefront of this textile revolution stands 300D Oxford Fabric—a material that has become synonymous with resilience and adaptability. In this comprehensive exploration, we will unravel the intricacies of 300D Oxford Fabric, delving into its composition, applications, advantages, customization process, and the meticulous manufacturing journey that brings it to life.

Composition and Characteristics

The Fabric of Possibilities

In the intricate tapestry of product manufacturing, the choice of fabric plays a pivotal role in determining the success and longevity of the end result. As industries demand materials that can withstand the test of time and diverse environments, 300D Oxford Fabric has emerged as a stalwart, offering a myriad of possibilities across an array of applications.

Unpacking “300D”

At the heart of 300D Oxford Fabric is a designation that holds the key to its exceptional qualities—300D. This specification signifies a fabric woven with 300 fibers per inch, setting it apart from its counterparts. Before we delve deeper into its applications and advantages, let’s first understand the composition and construction that make 300D Oxford Fabric a trailblazer in the textile realm.

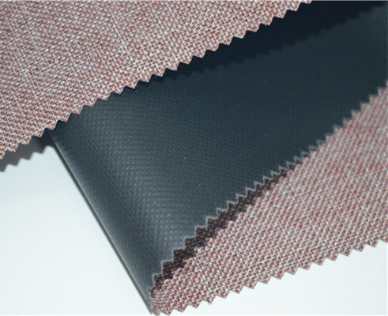

The Symphony of Materials

300D Oxford Fabric is a harmonious blend of carefully chosen materials, meticulously crafted to deliver unparalleled performance. At its core lies a foundation of polyester, chosen for its durability and versatility. But what elevates this fabric to a league of its own is the application of coatings, often in the form of Polyurethane (PU) or Polyvinyl Chloride (PVC). These coatings not only enhance the fabric’s structural integrity but also bestow upon it the coveted attributes of water resistance and weatherproofing.

Woven Excellence

The strength of 300D Oxford Fabric emanates from its intricate weaving process. The meticulous interlacing of fibers creates a tight, resilient structure capable of withstanding the rigors of daily use. This weaving technique not only contributes to the fabric’s durability but also lays the groundwork for customization—a feature we’ll delve into later.

Endless Applications: Where 300D Oxford Fabric Shines

Versatility in Design

300D Oxford Fabric stands as a versatile canvas for manufacturers and designers alike. Its adaptability allows for a broad spectrum of applications, making it a staple in various industries. From fashion to outdoor gear, the fabric seamlessly integrates into products where durability, style, and functionality converge.

Bags and Backpacks

In the world of bags and backpacks, where resilience is non-negotiable, 300D Oxford Fabric takes the spotlight. Its ability to withstand the daily hustle and bustle while providing a sleek and lightweight design makes it a top choice for manufacturers aiming to marry durability with aesthetics.

Luggage

For the travel industry, where products are subjected to the rigors of diverse environments, 300D Oxford Fabric proves its mettle. The fabric’s robustness ensures that luggage can endure the wear and tear associated with frequent travel, offering a reliable companion to jet-setters and adventurers alike.

Tents and Outdoor Products

Outdoor enthusiasts demand gear that can stand up to the elements, and 300D Oxford Fabric rises to the challenge. From tents that shield against the elements to various outdoor products requiring a durable exterior, this fabric weaves its protective magic, enhancing the user experience in the great outdoors.

Raincoats and Weather-Resistant Apparel

Staying dry in unpredictable weather conditions is a universal concern. 300D Oxford Fabric, with its water-resistant coating, becomes a trusted ally in crafting raincoats and weather-resistant apparel. It ensures wearers stay stylishly shielded from the rain while navigating urban landscapes or exploring nature.

Unveiling Unmatched Advantages

Exceptional Resistance

The hallmark of 300D Oxford Fabric is its exceptional resistance. The fabric’s ability to withstand wear, tear, and harsh environmental conditions speaks volumes about its longevity. Whether it’s enduring the hustle of daily urban life or braving the elements in the great outdoors, products made from 300D Oxford Fabric excel in resilience.

Weather Resilience

The PU or PVC coating on 300D Oxford Fabric extends its capabilities beyond durability. This coating provides a shield against rain, ensuring that products made from this fabric maintain their integrity even in adverse weather conditions. The fabric’s weather resilience makes it a standout choice for products that need to perform outdoors.

Durability without Bulk

One of the remarkable features of 300D Oxford Fabric is its ability to offer durability without adding unnecessary bulk. This becomes particularly crucial in products like bags and backpacks, where users seek a sleek and lightweight design without compromising on robustness.

Customization Possibilities

The beauty of 300D Oxford Fabric lies not only in its inherent qualities but also in its flexibility for customization. Manufacturers can play with a palette of finishes, colors, and additional features, tailoring products to specific market demands. This adaptability ensures that the fabric can align seamlessly with diverse design visions.

Tailoring Excellence: The Customization Journey

Understanding Customer Requirements

At the heart of our commitment to excellence lies a personalized approach to customization. We initiate the process by thoroughly understanding our client’s requirements. This involves engaging in detailed discussions to comprehend their specific needs, applications, and desired outcomes for the 300D Oxford Fabric.

Providing Options

Once we have a comprehensive understanding of the client’s vision, we offer a spectrum of choices to tailor the fabric precisely to their specifications. This includes providing options for color, thickness, and coating types. The color palette is extensive, allowing clients to choose hues that align with their brand identity or design preferences. Thickness options cater to diverse applications, ensuring the fabric meets the required durability standards. Additionally, clients can select from different coating types, such as Polyurethane (PU) or Polyvinyl Chloride (PVC), based on the intended use of the fabric.

Collaborative Creation

Our customization process is not just transactional; it’s a collaborative journey. We engage in a seamless exchange of ideas, working hand-in-hand with the client to bring their vision to life. Whether it’s refining color choices, adjusting thickness to meet specific performance criteria, or selecting the ideal coating for weather resistance, we prioritize a collaborative methodology. This ensures that every aspect of the fabric aligns with the client’s requirements and creates the desired aesthetic and functional impact.

Sample Approval

Transparency is key in our customization process. Before proceeding with full-scale production, we provide clients with samples based on the agreed-upon specifications. This allows them to physically assess the look, feel, and performance of the customized 300D Oxford Fabric. It’s a crucial step in the process, offering clients the opportunity to make any final adjustments or approvals before moving forward.

Efficient Production Execution

Once the client gives the green light, our state-of-the-art production facilities kick into high gear. Our skilled artisans leverage advanced manufacturing technologies to ensure precision and consistency in every roll of 300D Oxford Fabric. The customization details, including color, thickness, and coating, are meticulously implemented to produce a fabric that not only meets but exceeds client expectations.

Quality Assurance

Throughout the customization and production process, quality assurance remains a constant priority. Our fabrics undergo rigorous quality checks at various stages to guarantee they adhere to international standards. From color consistency to coating application, every detail is scrutinized to ensure the final product aligns with the client’s vision and our commitment to delivering excellence.

This collaborative and transparent customization process ensures that each roll of 300D Oxford Fabric is not just a product; it’s a tailored solution designed to elevate our client’s offerings in the market. Connect with us, and let’s embark on a journey of customization that transforms your vision into a textile reality.

Crafting Excellence: The Art of Manufacturing 300D Oxford Fabric

Material Selection

The journey of 300D Oxford Fabric begins with the careful selection of materials. Quality is the cornerstone of our manufacturing process. Polyester, chosen for its durability and versatility, forms the base of the fabric. This foundational material undergoes a meticulous evaluation process to ensure it meets our stringent standards, setting the stage for the creation of a fabric that stands apart in the industry.

Weaving and Coating

The weaving process is where the magic happens. Our skilled artisans employ precision techniques to interlace the polyester fibers, creating a tight, durable structure. This unique weaving method not only contributes to the fabric’s strength but also provides the foundation for the customization options that set 300D Oxford Fabric apart.

Following the weaving, the fabric undergoes a transformative step—the application of coatings. Polyurethane (PU) or Polyvinyl Chloride (PVC) coatings are carefully layered onto the fabric, imparting water-resistant and weatherproof qualities. This stage enhances the fabric’s durability, making it a reliable choice for products that need to withstand diverse environmental conditions.

Quality Control

Quality is non-negotiable in our manufacturing process. At every stage, our products undergo rigorous quality control measures. From the selection of raw materials to the final inspection before shipping, we ensure that each roll of 300D Oxford Fabric meets and exceeds international standards. Certifications and adherence to industry benchmarks underscore our commitment to delivering excellence.

Economic Viability: Unraveling the Cost-effectiveness

While there may be an initial investment, the decision to choose 300D Oxford Fabric proves to be cost-effective over time. Its abrasion resistance minimizes maintenance costs significantly, and the extended lifespan of products manufactured with this fabric enhances overall cost-effectiveness for manufacturers.

Initial Investment

While the initial cost of acquiring and integrating 300D Oxford Fabric into the manufacturing process may be slightly higher compared to other materials, it’s essential to view this as an investment rather than a mere expense.

Long-Term Durability

The key factor contributing to the cost-effectiveness of 300D Oxford Fabric is its remarkable durability. Products crafted from this fabric exhibit enhanced resistance to wear and tear, ensuring a prolonged lifespan compared to alternative materials.

Maintenance Cost Reduction

The inherent abrasion resistance of 300D Oxford Fabric translates into lower maintenance costs over time. Products made from this fabric are less prone to damage, reducing the need for frequent repairs or replacements.

Extended Product Lifespan

The longevity of products manufactured with 300D Oxford Fabric is a game-changer. With a fabric that can withstand the rigors of daily use and adverse environmental conditions, manufacturers experience a significant increase in the lifespan of their end products.

Overall Manufacturing Cost-effectiveness

Despite the initial investment, the extended lifespan and reduced maintenance costs contribute to overall manufacturing cost-effectiveness. Manufacturers benefit from a higher return on investment as they can produce durable, long-lasting products without incurring additional expenses for frequent repairs or replacements.

Ensuring Consistency: Navigating the Supply Chain Stability

Our factory is committed to streamlining the supply chain and implementing an efficient manufacturing process, contributing to competitive pricing. We recognize the importance of cost-effectiveness throughout the production chain and strive to deliver cost-competitive solutions to our customers without compromising on quality.

Efficient Supply Chain Management

Our dedication to supply chain efficiency starts from the sourcing of raw materials to the delivery of the final product. By implementing robust supply chain management practices, we ensure a smooth and streamlined process, reducing unnecessary delays and costs.

Competitive Pricing

The efficiency in our supply chain directly translates into competitive pricing for our products. We leverage our streamlined processes to minimize operational costs, allowing us to offer our customers prices that are not only competitive but also reflective of the value they receive.

Cost-Effective Manufacturing

Understanding the intricacies of cost-effectiveness in the manufacturing process, we have implemented strategies to optimize efficiency without compromising on quality. This approach enables us to produce high-quality products at a cost that remains competitive within the market.

Quality Assurance in Cost-Efficiency

While cost-effectiveness is a priority, we maintain a steadfast commitment to quality assurance. Our stringent quality control measures are integrated into every stage of the supply chain, ensuring that our products meet or exceed industry standards without inflating costs.

Transparent Cost Structures

Transparency is crucial in establishing trust with our clients. We maintain clear and transparent cost structures, providing our customers with a comprehensive understanding of where their investment goes. This openness fosters a collaborative partnership where clients recognize the value and cost-effectiveness of our offerings.

Market Trends and Developments

Analyzing the Growth Trajectory of 300D Oxford Fabric

Evolving Applications

The market for 300D Oxford Fabric is undergoing a significant transformation with evolving applications. Beyond its traditional use in bags, luggage, and outdoor gear, there is a discernible trend towards exploring innovative applications. Industries are increasingly recognizing the versatile properties of 300D Oxford, leading to its incorporation into new and diverse product categories.

Sustainability Emphasis

With sustainability taking center stage in consumer preferences, there is a growing demand for eco-friendly materials. 300D Oxford Fabric, known for its durability and potential for recyclability, positions itself as a sustainable choice. The market trend reflects a heightened interest in materials that not only perform well but also align with environmentally conscious values.

Advancements in Coating Technologies

Ongoing advancements in coating technologies further enhance the appeal of 300D Oxford Fabric. The market is witnessing increased interest in fabrics with advanced coatings that offer additional functionalities, such as antimicrobial properties, UV resistance, and improved water repellency. As a result, 300D Oxford Fabric continues to be at the forefront of these innovations.

Outdoor and Adventure Gear

The demand for high-performance materials in outdoor and adventure gear is a prevailing trend. 300D Oxford Fabric’s resilience against wear, tear, and adverse weather conditions aligns perfectly with the requirements of this sector. The fabric’s penetration into this market segment is expected to grow, driven by a consumer base that values both performance and durability in their outdoor equipment.

Positioning of 300D Oxford Fabric in the High-Performance Fabric Trend

Meeting Industry Demand

The industry’s increasing appetite for high-performance fabrics positions 300D Oxford Fabric as a frontrunner. Its proven durability, weather resistance, and customization options make it a go-to choice for manufacturers looking to meet the escalating demand for materials that excel in performance without compromising on quality.

Versatility and Adaptability

One of the key strengths of 300D Oxford Fabric lies in its versatility. Its adaptability to diverse applications positions it as a strategic player in an industry where flexibility is paramount. As market trends continue to shift and new applications emerge, the fabric’s versatility ensures it remains relevant and in-demand.

Resonance with Consumer Values

The consumer’s growing emphasis on longevity, sustainability, and performance aligns seamlessly with the inherent qualities of 300D Oxford Fabric. As consumers become more discerning in their choices, the fabric’s ability to check multiple boxes—durability, environmental consciousness, and customization—positions it as a material of choice in the evolving market landscape.

Collaborative Innovation

The evolving market trends underscore the importance of collaborative innovation. Manufacturers, designers, and fabric producers working together to push the boundaries of what 300D Oxford Fabric can achieve ensure its continued relevance in an industry driven by innovation and consumer preferences.

Customer Testimonials: Real Voices, Real Experiences

Customer Testimonial 1:

“I recently purchased a backpack made from 300D Oxford Fabric, and I couldn’t be happier with my choice. The fabric’s performance is truly unmatched – it has weathered rain, rough handling, and daily commutes with ease. What’s equally impressive is the sleek design and stylish appearance that haven’t faded over time. 300D Oxford Fabric has become a symbol of durability and style for me.”

Customer Testimonial 2:

“As an avid hiker, I’ve gone through my fair share of gear, and I must say, 300D Oxford Fabric has set a new standard. My tent, made from this remarkable fabric, has endured extreme weather conditions without a hint of wear. It’s reassuring to have gear that not only withstands the elements but exceeds expectations. I highly recommend 300D Oxford Fabric for anyone seeking reliability in their outdoor equipment.”

Customer Testimonial 3:

“I run a busy lifestyle, and my daily bag has been a constant companion. Switching to a bag crafted from 300D Oxford Fabric has been a game-changer. The fabric’s durability is evident – no fraying, no tearing. The attention to detail in the stitching and the water-resistant coating make it a reliable choice for my on-the-go lifestyle. Exceptional quality and performance at a price that won’t break the bank. Thumbs up!”

Conclusion

In this exploration of 300D Oxford Fabric, we’ve journeyed from its definition to its applications, advantages, customization possibilities, and the intricate manufacturing process that brings it to life. As a versatile, durable, and customizable material, 300D Oxford Fabric continues to redefine industry standards.

As you consider the ideal fabric for your products, let 300D Oxford Fabric be the thread that weaves together resilience, adaptability, and style. Connect with us at Yirun Textile to explore how this remarkable fabric can elevate the performance and aesthetics of your offerings.

Whether you are in the fashion industry seeking a durable yet chic material, a luggage manufacturer requiring resilience for frequent travel, or an outdoor gear designer aiming to create products that stand up to the elements, 300D Oxford Fabric is the answer.

As we continue to innovate and refine our manufacturing processes, 300D Oxford Fabric remains at the forefront of textile excellence. It’s not just a fabric; it’s a testament to the fusion of craftsmanship and technology, offering a canvas for creativity and durability.

Explore the possibilities, embrace the resilience, and elevate your products with the unmatched qualities of 300D Oxford Fabric.