You may also find:

What is 190T Oxford Fabric?

What is 300D Oxford Fabric?

What is 420D Oxford Fabric?

What is 600D Oxford Fabric?

What is 900D Oxford Fabric?

What is 1200D Oxford Fabric?

What is 1680D Oxford Fabric?

What is PU Coated Fabric?

What is PVC Coated Fabric?

Introduction

In the vast world of textiles, where innovation meets functionality, the spotlight often falls on fabrics like Oxford, renowned for its durability and versatility. Among the various deniers available, 210D Oxford Fabric stands out as a popular choice for a myriad of applications. In this comprehensive blog, we delve into the intricacies of 210D Oxford Fabric, exploring its composition, applications, comparisons, quality assurance, sustainability, and much more.

Understanding Oxford Fabric

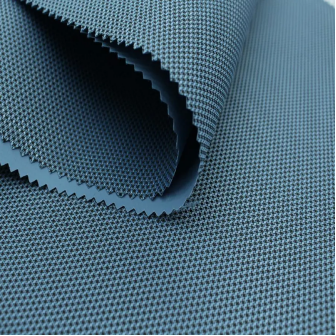

Oxford Fabric, in its essence, is a woven textile known for its strength, durability, and versatile nature. It has become the backbone of many industries due to its ability to withstand wear and tear while offering a range of design possibilities. The term “Oxford” itself originates from the fabric’s historical association with the prestigious Oxford University, showcasing its robust and enduring characteristics.

Exploring the “D” Denier Measurement

A key aspect that defines the strength and thickness of a fabric is the Denier, denoted by the letter “D.” In the case of 210D Oxford Fabric, the “D” refers to Denier, a unit of measurement indicating the linear mass density of fibers. The 210D specification indicates that a single strand of the fabric weighs 210 grams per 9000 meters. This measurement is crucial as it directly influences the fabric’s strength and performance, making it a critical consideration for manufacturers seeking reliability in their products.

Features of 210D Oxford Fabric

The allure of 210D Oxford Fabric lies in its unique set of features that make it a preferred choice for various applications. Firstly, its durability is unparalleled, making it resistant to abrasion and wear, thus ensuring a prolonged lifespan for products crafted from it. Additionally, the fabric boasts exceptional strength without compromising on flexibility, allowing for the creation of products that can withstand the rigors of daily use while maintaining a sleek and comfortable design.

Introduction to the Performance Characteristics of 210D Oxford Fabric

210D Oxford Fabric is renowned for its exceptional performance characteristics, making it a top choice for manufacturers across various industries. From its robust construction to its versatility, this specialized textile offers a range of features that elevate the quality and functionality of the end products. Let’s delve into the key performance characteristics of 210D Oxford Fabric:

Durability

210D Oxford Fabric is engineered with durability at its core. The fabric’s ability to withstand wear and tear, abrasion, and frequent use ensures that products made from it maintain their structural integrity over an extended period. This durability makes it particularly suitable for applications where longevity is crucial.

Strength-to-Weight Ratio

Despite its lightweight composition, 210D Oxford Fabric boasts an impressive strength-to-weight ratio. This characteristic is essential for products where a balance between sturdiness and weight is critical, such as in outdoor gear like backpacks and tents. It allows for the creation of products that are both robust and portable.

Abrasion Resistance

The fabric’s excellent resistance to abrasion is a testament to its durability. Whether it’s a backpack dragged along rocky trails or a tent exposed to rough surfaces, 210D Oxford Fabric maintains its quality, minimizing the impact of friction and abrasion on the material.

Flexibility

Flexibility is a key performance characteristic that enhances the versatility of 210D Oxford Fabric. The fabric can easily adapt to various manufacturing processes and design requirements, allowing for the creation of products with intricate shapes and contours without sacrificing strength or durability.

Water-Resistance

A standout feature of 210D Oxford Fabric is its exceptional water-resistant properties. The fabric serves as a reliable shield against moisture, making it an ideal choice for outdoor products such as raincoats, tents, and bags. This water-resistance ensures that the contents remain dry, providing practical functionality in various weather conditions.

Common Uses in Outdoor Products

Moving beyond the technical specifications, let’s explore where 210D Oxford Fabric truly shines—its diverse range of applications in crafting outdoor products. Manufacturers across the globe have embraced this fabric for its ability to meet the demanding requirements of various industries.

Bags, backpacks, and luggage

The robust nature of 210D Oxford Fabric makes it an ideal choice for crafting bags and backpacks that can endure the challenges of everyday use. Its strength ensures that your belongings remain secure, even in the most demanding environments. From school backpacks to professional travel luggage, this fabric provides the necessary foundation for reliability.

Tents and shelters

When it comes to outdoor adventures, the quality of a tent can make or break the experience. 210D Oxford Fabric is a popular choice for tent manufacturing due to its waterproof properties and resistance to harsh weather conditions. Campers and outdoor enthusiasts can trust that their shelter will withstand the elements, providing a secure refuge during their journeys.

Raincoats and outerwear

Staying dry during unpredictable weather is a must, and 210D Oxford Fabric excels in creating durable and weather-resistant raincoats. Its water-resistant properties, coupled with its breathability, make it an excellent choice for outerwear that keeps individuals comfortable and protected in varying climates.

Tailoring to Your Specifications

Embarking on the journey of crafting custom 210D Oxford Fabric involves a meticulous process aimed at understanding and fulfilling the unique requirements of our valued clients. Our commitment to delivering tailored solutions extends to every step of the customization process:

Understanding Customer Requirements

Our customization journey begins with a thorough understanding of our client’s specifications. We engage in open communication to comprehend their unique needs, application requirements, and any specific attributes they are seeking in the 210D Oxford Fabric.

Providing Color, Thickness, and Coating Options

Offering a diverse array of choices is fundamental to our customization approach. Clients have the flexibility to choose from an extensive palette of colors, ensuring that the final product aligns with their brand or design preferences. Thickness options are presented, allowing clients to tailor the fabric’s weight to suit the intended application. Additionally, a range of coating types, including PU (Polyurethane) or PVC (Polyvinyl Chloride), are provided, each contributing unique properties to the fabric.

Collaborative Creation of Desired Fabric

Collaboration is key to creating the ideal 210D Oxford Fabric. We work closely with clients to amalgamate their vision with our technical expertise. This collaborative phase involves discussions on design elements, functional requirements, and performance expectations. Our team of experts provides insights and recommendations to optimize the fabric for the intended use.

Production Process for 210D Oxford Fabric: Crafting Quality through Precision

The production process for 210D Oxford Fabric involves a series of intricate steps, encompassing both the textile and coating phases. Understanding these key processes is essential to appreciating the quality and versatility that define this specialized fabric.

Textile Manufacturing Process

Material Selection: The process commences with the careful selection of high-quality polyester yarns. The choice of raw materials is pivotal, influencing the fabric’s strength, durability, and overall performance.

Weaving: The selected yarns undergo a meticulous weaving process, adopting the Oxford weave pattern. This pattern, characterized by a basket-like structure, contributes to the distinctive texture and strength of 210D Oxford Fabric.

Denier Measurement: The woven fabric is then subjected to denier measurement. In the case of 210D Oxford Fabric, the “D” refers to Denier, indicating the linear mass density of the fibers. This measurement determines the thickness and strength of the fabric.

Coating Technology

Coating Application: The next critical step involves applying a protective coating to the woven fabric. Manufacturers typically offer a choice between Polyurethane (PU) and Polyvinyl Chloride (PVC) coatings. PU coating provides flexibility and breathability, while PVC coating offers robust water resistance.

Coating Techniques: The application of coatings requires precision. Techniques such as calendaring or lamination are employed to evenly apply the coating, ensuring consistent performance characteristics across the entire fabric surface.

Quality Control Measures

Testing and Inspection: Throughout the manufacturing process, rigorous testing and inspection are conducted. This includes assessing the strength, thickness, color consistency, and coating adhesion. Any deviations from quality standards are identified and addressed promptly.

Prototyping and Sample Testing: Before full-scale production, prototypes of the 210D Oxford Fabric are created. These samples undergo thorough testing to ensure they meet the client’s specifications. This phase allows for adjustments and refinements to achieve the desired characteristics.

Key Factors Influencing Fabric Quality

Yarn Quality: The quality of the polyester yarns directly impacts the fabric’s durability and tensile strength. Careful sourcing and quality checks at this stage are critical.

Weaving Precision: The precision of the weaving process, especially in achieving the Oxford weave pattern, contributes to the fabric’s texture and overall structural integrity.

Coating Thickness and Distribution: The even application of the coating, with precise thickness, is crucial. This directly affects the fabric’s water resistance, flexibility, and other performance attributes.

Adherence to Denier Specifications: Strict adherence to the specified denier measurement ensures that the fabric meets the required thickness and strength criteria.

Quality of Coating Material: The choice of coating material (PU or PVC) and its quality directly influence the fabric’s final properties, such as water resistance and flexibility.

Cost-Effectiveness of 210D Oxford Fabric: A Long-Term Investment

Despite initial investments, the choice of 210D Oxford Fabric has proven to be a cost-effective decision over time. Its abrasion resistance minimizes maintenance costs significantly, and the extended lifespan of products manufactured with this fabric enhances manufacturers’ overall cost-effectiveness.

Reduced Maintenance Costs

The exceptional abrasion resistance of 210D Oxford Fabric stands as a cornerstone in cost reduction for manufacturers. This remarkable quality ensures that products created with this fabric maintain their structural integrity, effectively withstanding the challenges of daily use and environmental stressors. By mitigating wear and tear, the fabric significantly diminishes the need for frequent repairs or replacements, offering manufacturers a substantial advantage in long-term savings. This durability not only elevates the reliability of the end products but also enhances the overall cost-effectiveness of manufacturing processes, positioning 210D Oxford Fabric as a strategic choice for sustainable and economically efficient production.

Extended Product Lifespan

Products crafted with 210D Oxford Fabric exhibit an extended lifespan, ensuring that end-users enjoy reliable performance over an extended period. This longevity not only enhances the reputation of the brand but also reduces the need for frequent replacements, contributing to cost-effectiveness.

Lower Replacement Frequency

The inherent robustness of 210D Oxford Fabric serves as a protective shield for products, substantially minimizing the risks of damage or degradation. This quality not only ensures the longevity of items but also translates to a tangible reduction in the frequency of replacements. The diminished need for frequent replacements directly correlates to lower costs in manufacturing and distribution. Manufacturers benefit from decreased production expenses and logistics costs, making 210D Oxford Fabric an economically sound choice. This resilience not only enhances the sustainability of products but also reinforces the fabric’s position as a cost-effective and reliable solution for diverse manufacturing applications.

Long-Term Investment Returns

Viewed as a long-term investment, the utilization of 210D Oxford Fabric pays off over time. The reduced costs in maintenance, repairs, and replacements, coupled with satisfied customers, contribute to a positive return on investment that far exceeds the initial financial outlay.

Supply Chain Stability: Enhancing Efficiency and Cost-Competitiveness

Our factory is dedicated to streamlining the supply chain and optimizing manufacturing processes, contributing to competitive pricing. Recognizing the critical importance of cost-effectiveness in the production chain, we strive to deliver cost-competitive solutions to our customers without compromising on quality.

Streamlined Supply Chain

We prioritize the simplification of our supply chain, ensuring a seamless and efficient flow of materials and resources. This strategic approach minimizes delays, reduces operational complexities, and ultimately enhances the overall stability of our supply chain.

Efficient Manufacturing Processes

Our commitment to efficiency extends to manufacturing processes, where we employ lean and agile methodologies. This results in reduced production lead times, optimized resource utilization, and, consequently, cost savings that are passed on to our customers in the form of competitive prices.

Cost-Competitive Pricing

Understanding the significance of cost competitiveness in the market, we strategically manage our production costs. By identifying areas for optimization and efficiency improvement, we ensure that our pricing remains attractive while maintaining the high standards of quality our customers expect.

Importance of Cost-Efficiency

We recognize that cost-efficiency is not only about minimizing expenses but also about delivering value to our customers. Our focus on cost-effectiveness enables us to provide reliable and cost-competitive solutions, ultimately fostering long-term partnerships with our clients.

Quality Assurance in Cost-Effective Solutions

In our relentless pursuit of cost competitiveness, we uphold an unwavering commitment to quality assurance. Recognizing that the essence of true value lies in the marriage of affordability and excellence, we prioritize stringent quality control measures throughout our manufacturing processes. This dedication ensures that our cost-effective solutions do not compromise the integrity, durability, or performance of the end products. By seamlessly blending cost competitiveness with uncompromising quality standards, we guarantee that our customers receive not just economically viable solutions but products that consistently meet and exceed their expectations, fostering trust and long-term satisfaction.

Market Trends and Development: Positioning 210D Oxford Fabric in a Dynamic Landscape

Within the dynamic textile industry, a careful examination of market trends underscores a significant surge in demand for high-performance fabrics. In this evolving landscape, 210D Oxford Fabric stands out as a leading choice, asserting its prominence and meeting the dynamic demands of the industry.

Versatility Unleashed

Going beyond its durable construction, 210D Oxford Fabric showcases exceptional versatility, seamlessly adapting to a diverse range of applications. From bags to backpacks, tents, and beyond, its adaptability proves invaluable in an era where customization is paramount, catering to the varied needs of different industries.

Reliable and Future-Ready

In the midst of technological shifts and evolving consumer preferences, the reliability of 210D Oxford Fabric remains steadfast. Its consistent performance and ability to meet changing demands position it as a robust solution for manufacturers navigating the intricacies of a dynamic market. Looking ahead, 210D Oxford Fabric is poised to meet the sustained demand for high-performance materials, solidifying its role as a reliable cornerstone for the future of the textile industry.

Customer Testimonials: Embracing Excellence with 210D Oxford Fabric

In the voices of our esteemed customers, the praise for 210D Oxford Fabric resounds, echoing the satisfaction and admiration for this exceptional textile. Here are insights into the sentiments shared by those who have experienced the distinct qualities of 210D Oxford Fabric:

Enduring Durability

“Unmatched durability! Our backpacks endure the daily grind with grace, and it’s all thanks to the robust nature of 210D Oxford Fabric. It’s not just a material; it’s a reliability guarantee.”

Versatility in Every Stitch

“From luggage to tents, the adaptability of 210D Oxford Fabric is nothing short of impressive. It seamlessly transitions across our product line, proving its versatility and making it an invaluable asset in our manufacturing.”

Weather-Defying Water Resistance

“210D Oxford Fabric is our go-to choice for raincoats, and the water resistance is a game-changer. Customers appreciate staying dry in style, and we appreciate the reliability this fabric brings to our designs.”

Strength without the Weight

“Our technical apparel demands strength without compromise on weight. 210D Oxford Fabric delivers exactly that. It’s a relief to have a material that doesn’t weigh down our products but ensures they stand strong against any challenge.”

Conclusion

In conclusion, 210D Oxford Fabric emerges as a versatile and reliable choice for manufacturers seeking a balance between strength, durability, and cost-effectiveness. From its origins in the prestigious Oxford University to its widespread use in crafting outdoor products, this fabric has proven its mettle across diverse industries.

As you consider your options for fabric sourcing, keep in mind the unparalleled advantages that 210D Oxford Fabric brings to the table. Its ability to withstand the rigors of outdoor use, coupled with its cost-effectiveness and eco-friendly attributes, positions it as a standout choice for bags, backpacks, luggage, tents, raincoats, and more.

At Yirun Textile, we take pride in offering 210D Oxford Fabric that not only meets but exceeds industry standards. Our commitment to quality, coupled with faster lead times and competitive pricing, positions us as your trusted manufacturing partner. Explore the possibilities with 210D Oxford Fabric, and let’s embark on a journey of innovation and reliability together.